Application and analysis of paper bag machine

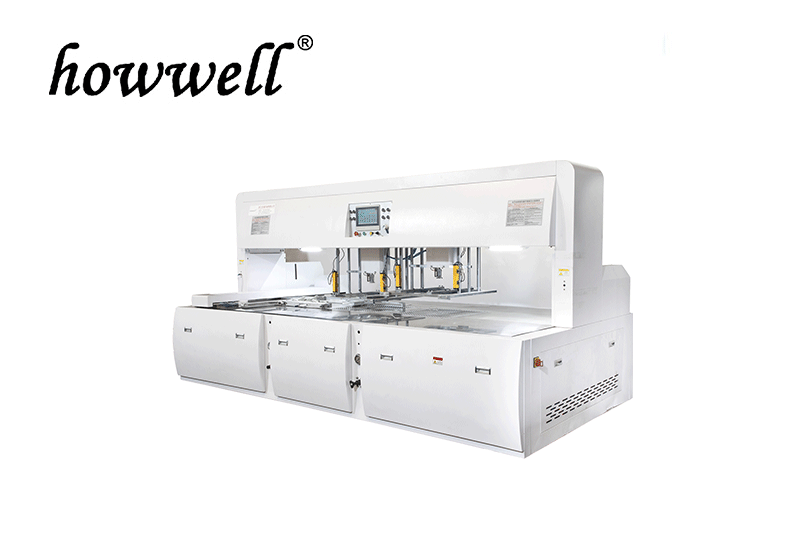

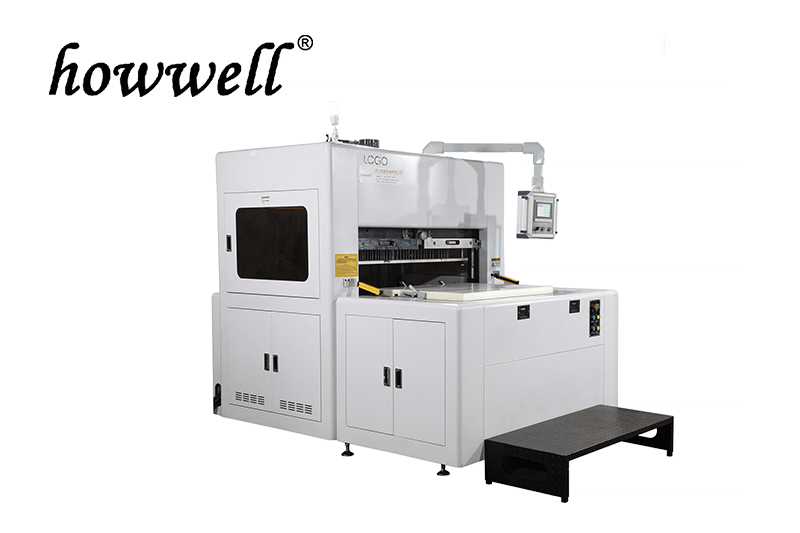

The paper bag machine uses the printed sheet of paper as raw material, which is automatically fed by Feida, transported through the paper feeding platform, and then uses the front gauge and side gauge to accurately position the sheet, and feed it into the crimping roller to press the vertical line. Then automatically brush glue (can be sprayed with hot melt glue), form, automatically fold the organ edge, automatically form a tube, and then transport it to the bottom device through the push rod for pulling the bottom, applying the bottom glue, and forming the bottom, and the finished paper bag is completed at one time. This machine-made bag has high precision and high speed. It is the best equipment for processing clothing handbags and gift bags, and is your ideal business partner.

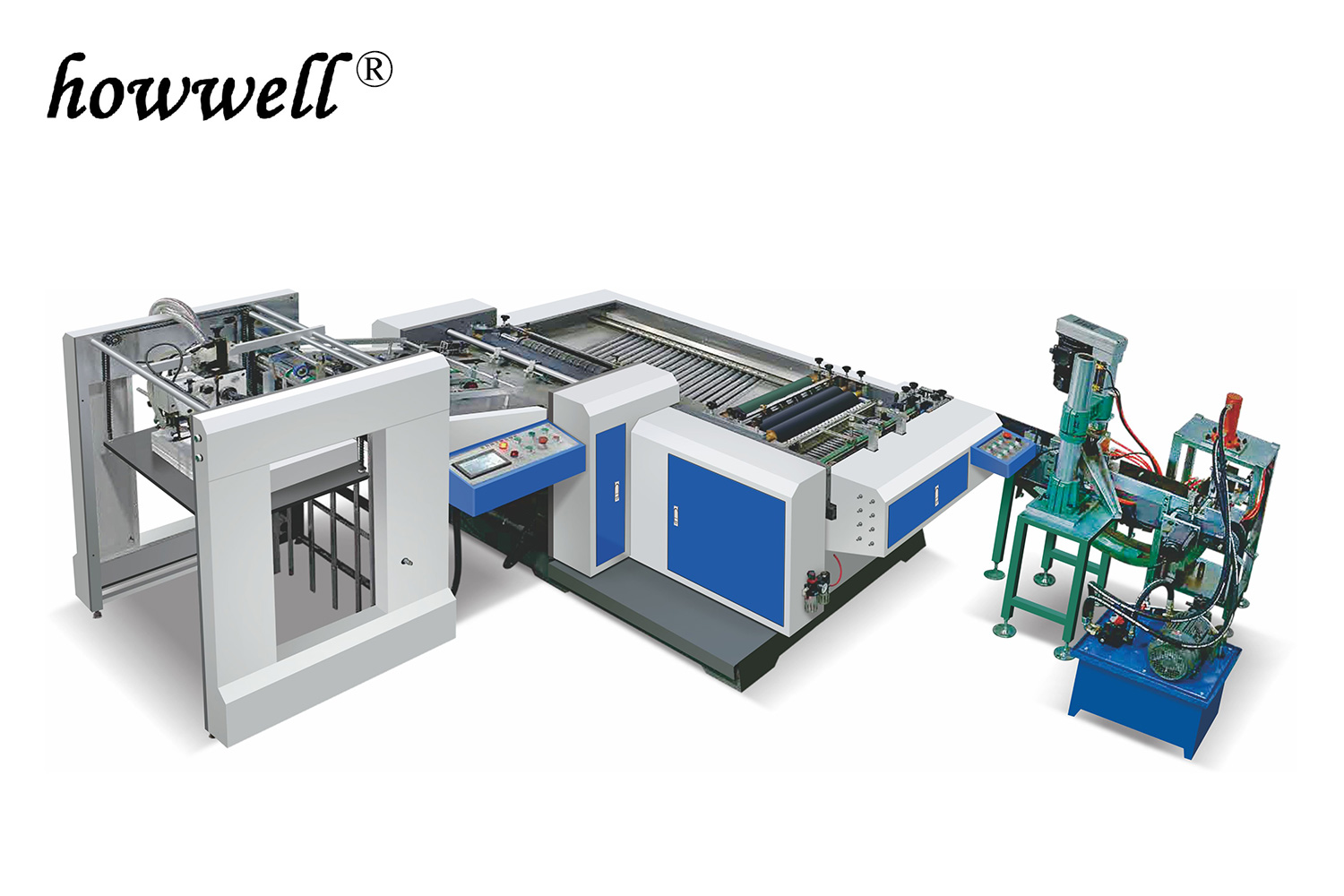

The paper bag machine uses base paper or printed roll paper as raw material, and the seamless steel tube can synchronously complete the square bottom paper bag with handle at one time. It is an ideal equipment for producing square bottom paper bag with handle. The machine uses the handle machine assembly to make the paper rope and the patch roll into a handle, and then sends the handle to the sticker unit through the conveying device; in the sticker unit, the primary color or printed roll paper is patched After the point is broken, the patch is glued, and the handle is automatically pasted, the host will glue the paper with the handle, form a paper tube, cut, creasing the bottom, glue the bottom, and form and transport the bottom of the bag. out of the bag.

The whole nickel sulfamate machine is controlled by the computer central control system, the running state is displayed and controlled by the touch screen, and the bag making length is controlled by the servo motor, thus ensuring that the machine can produce various specifications of portable paper bags.

Español

Español Français

Français