This machine features a continuous function of automatic paper suction gluing, creasing, bottom sticking and bag formation at a stroke. The machine has automatic force controlling machine and the function of color marking tracking.

Product description:

|

Model |

HWFD220 |

HWFD280 |

HWFD330 |

HWFD450 |

HWFD450B |

HWFD540 |

|

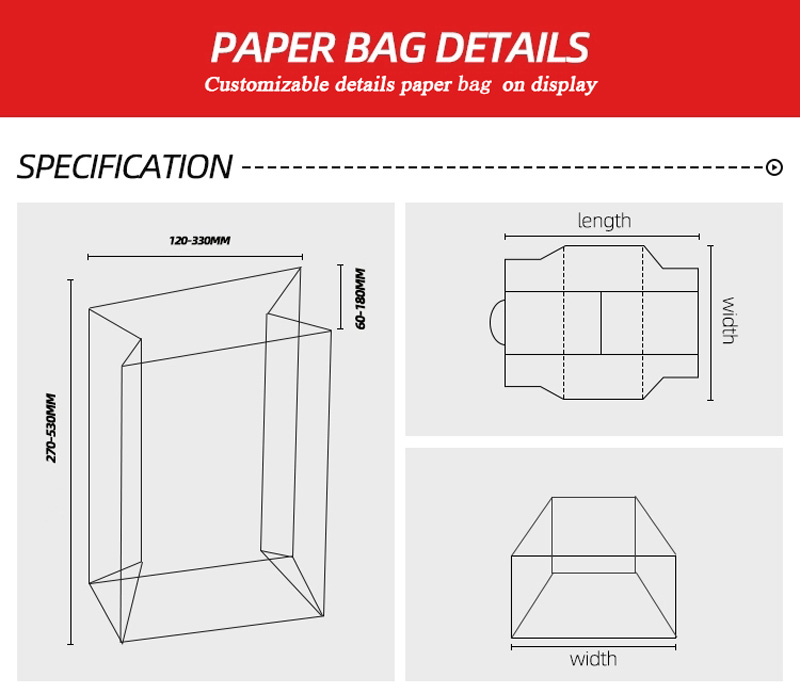

Bag Tube Length |

190-370mm |

270-530mm |

270-530mm |

285-530mm |

420-760mm |

420-760mm |

|

Bag Length |

150-320mm |

225-470mm |

225-470mm |

225-470mm |

320-680mm |

340-680mm |

|

Bag Width |

80-220mm |

120-280mm |

120-330mm |

220-450mm |

200-450mm |

250-540mm |

|

Bottom Width |

50-120mm |

60-160mm |

60-180mm |

80-220mm |

80-240mm |

120-260mm |

|

Side Edge Width |

20-30mm |

25-30mm |

25-30mm |

30mm |

30mm |

30-40mm |

|

Bottom Edge Width |

10-20mm |

15-25mm |

15-25mm |

20-30mm |

20-30mm |

20-30mm |

|

Paper Thickness |

50-130g/㎡ |

60-160g/㎡ |

60-160g/㎡ |

80-160g/㎡ |

80-160g/㎡ |

90-160g/㎡ |

|

Paper Inner Core Diameter |

ᴓ76mm(3”) |

ᴓ76mm(3”) |

76mm(3”) |

76mm(3”) |

76mm(3”) |

76mm(3”) |

|

Paper Roll Diameter |

ᴓ1300mm |

ᴓ1300mm |

ᴓ1300mm |

ᴓ1300mm |

ᴓ1300mm |

ᴓ1300mm |

|

Paper Roll Width |

280-710mm |

385-910mm |

385-1050mm |

630-1370mm |

590-1370mm |

770-1640mm |

|

Bag Making Speed |

30-200pcs/min |

30-180pcs/min |

30-160pcs/min |

30-150pcs/min |

30-120pcs/min |

30-120pcs/min |

|

Air Source |

≥0.12m³/m 0.6Mpa |

≥0.12m³/m 0.6Mpa |

≥0.12m³/m 0.6Mpa |

≥0.12m³/m 0.6Mpa |

≥0.12m³/m 0.6Mpa |

≥0.12m³/m 0.6Mpa |

|

Power Supply |

10kw |

12kw |

12kw |

12w |

16.5kw |

16.5kw |

|

Machine Weight |

5500kgs |

7000kgs |

8000kgs |

9000kgs |

10000kgs |

12000kgs |

|

Machine Dimension |

8000X2980X1800mm |

9700X2980X1900mm |

9800X3050X1900mm |

10200X3150X2200mm |

11265x3400x2200mm |

11250X3400X2160mm |

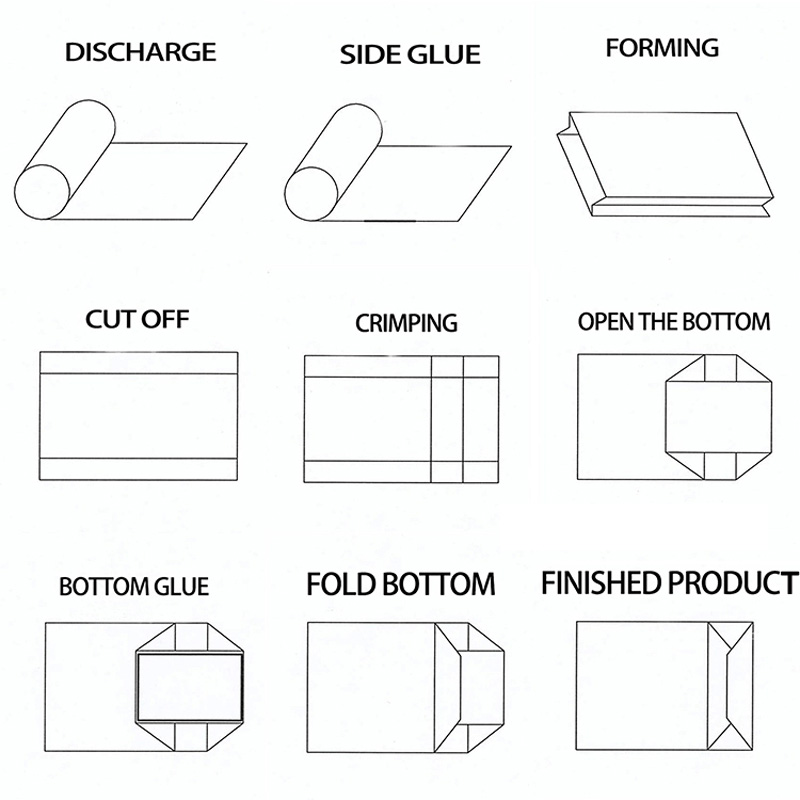

Forming Process:

Machine Details

Sample Picture:

PRODUCTS FEATURE:

OUR SERVICE:

OUR ADVANTAGE:

Packing:

Stretch film packing & in container.

FAQ:

Q:How is the quality of your machine?

A:Our company was founded 20 years ago, is quality for life. We choose world famous brand parts.And besides, we have our own quality inspector.Machine parts are checked one by one according to the drawings! Good quality and good after-sales help us obtain good reputation in the international market! We have a technical team of 11 person and at the same time cooperate with other Research Institutes. We are committed to providing customers with the best paper bag machine.

Q:Do you have related machine working VIDEO?

A:Yes, we will provide videos of machine commissioning, feeding and sample presentation.

Q:What is the delivery time?

A:As it is a large machine, it usually takes about 30 days.

Q:How do you solve the machine problem after your engineer leaving?

A:Generally speaking, there will be no problem after finish installing. In case you have any problem. You can contact our sales at any time. Our engineer will take a solution video according your description.

Paper bags are increasingly important in the 21st century because these bags are 100% reusable, recyclable and biodegradable, while being environmentally friendly an...

Reducing plastic is government and customer' top environmental concern.Using the paper products instead of the plastic products is a good choice.Firstly, the paper d...

During the period of widely using plastic products, the world saw the effects of non-biodegradable waste of plastic packaging on the global environment. There are so...

A paper bag is a bag made of paper, usually kraft paper. Paper bags are commonly used as shopping bags, packaging. Paper bags can be made from recycled paper, with s...

Paper carry bags are easily recyclable as compared to plastic carry bags and as an important role in environment. It is a very great opportunity to earn profit from ...