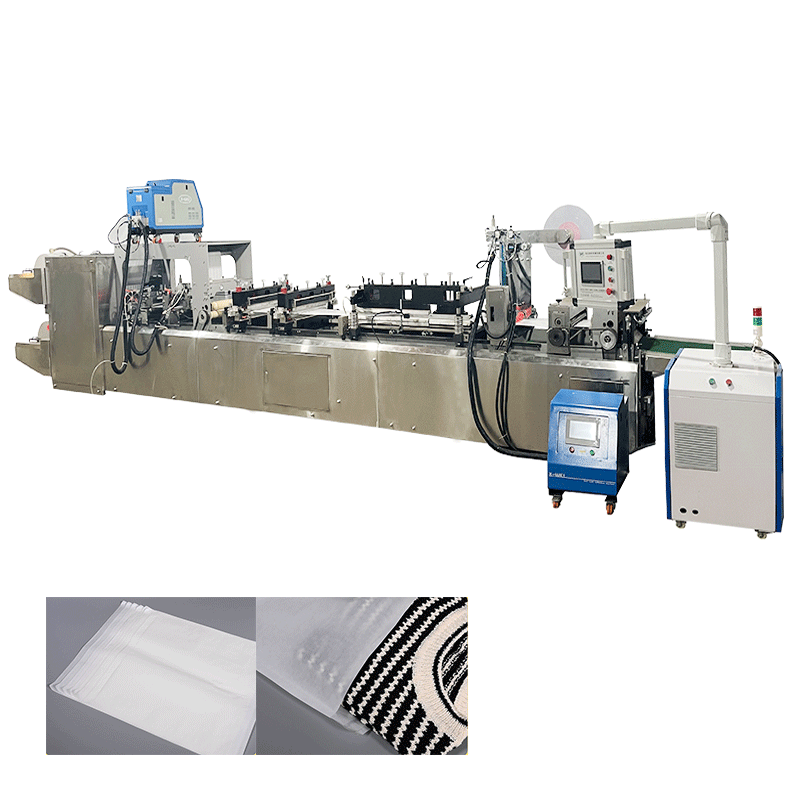

一、产品介绍 Product Presentation

三边封纸袋机是一种广泛应用于食品、医药、化工、日用品等诸多行业的包装机械设备,其特点在于具有三边自动封口的功能。

三边封纸袋机能够实现高效的包装生产。由于其自动化程度高,设备操作简便,并且在生产过程中可以实现对包装袋的快速制作和自动封口,因此可以极大地提高生产效率,节约时间和人力成本。

其次,该设备的操作简便,且可靠性高。三边封纸袋机通过电气控制和气动控制,能够自动完成包装袋的制作和封口工作,其操作也十分简单方便,无需繁琐的调试和维护,因此设备的可靠性和稳定性都非常高。

同时该设备具有灵活性和可扩展性。三边封纸袋机可用于多种规格的制袋,如长、宽、高不同的纸质袋、塑料袋等,同时也可以针对不同的包装需要进行定制和扩展,以适应不同的生产需求。

三边封纸袋机是一种高效、可靠、灵活且易于使用的包装设备,其在现代包装行业中得到越来越广泛的应用和推广。

Three-side sealing paper bag machine is a kind of packaging machinery and equipment widely used in many industries such as food, medicine, chemical industry, daily necessities, etc. It is characterized by the function of automatic three-side sealing.

The three-side paper bag sealing machine enables efficient packaging production. Due to its high degree of automation, easy operation of the equipment, and rapid production and automatic sealing of packaging bags during the production process, it can greatly improve production efficiency and save time and labor costs.

Secondly, the device is easy to operate and has high reliability. The three-side sealing paper bag machine can automatically complete the production and sealing of packaging bags through electrical control and pneumatic control. Its operation is also very simple and convenient, without cumbersome debugging and maintenance, so the reliability and stability of the equipment are very high.

At the same time, the device is flexible and expandable. The three-side sealing paper bag machine can be used to make bags of various specifications, such as paper bags with different lengths, widths and heights, plastic bags, etc. It can also be customized and expanded for different packaging needs to meet different production needs.

Three-side sealing paper bag machine is an efficient, reliable, flexible and easy-to-use packaging equipment, which has been more and more widely used and promoted in the modern packaging industry.

二、主要技术参数:Main Technical Parameters:

|

型号 Model |

XK-600 |

XK-1000 |

|

袋宽 Bag Width |

100-500mm |

150-800mm |

|

袋长 Bag Length |

150-550mm |

300-900mm |

|

机器速度 Machine Speed |

20-100pcs/min |

20-80pcs/min |

|

基材宽度 Substrate Width |

150-580mm |

300-900mm |

|

基材直径 Substrate diameter |

<600mm |

<1000mm |

|

电压 Voltage |

380V 三相四线 |

380V 三相四线 |

|

工作气源 Working air source |

≥0.12m³/min,0.6 (MPa) |

≥0.12m³/min,0.6 (MPa) |

|

总功率 Total Power |

14KW |

18KW |

|

整机重量 Total Weight |

4000kg |

5000kg |

|

机器尺寸 Machine Diameter(L*W*H) |

9000*1500*2200mm |

11000*1700*2200mm |

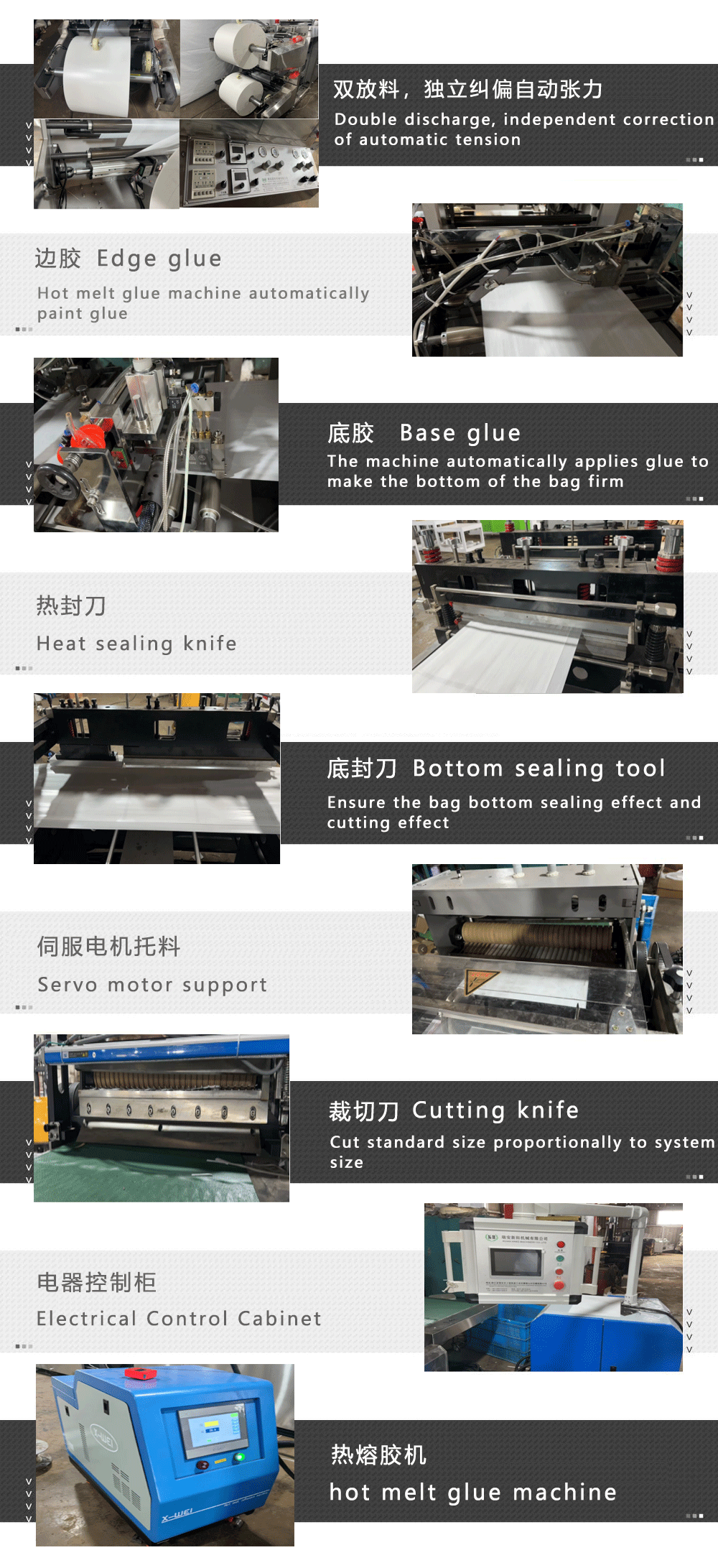

三、机器配置:Machine configuration

1.前后双放料,独立纠偏,自动张力,无料停机等功能;

Double feeding before and after, independent correction, automatic tension, no material stop and other functions;

Before and after discharge double traction, independent control;

The edge glue is coated by mobile hot melt glue and driven by servo;

The base glue is adjustable, and the hot melt glue is coated;

Two sets of heat sealing units make the sealing on both sides of the bag more uniform and firm;

The heat sealing unit at the bottom of the bag makes the glue coating at the bottom of the bag more uniform and firm;、

Bag mouth self-adhesive unit, independent hot melt adhesive machine, servo transfer and release paper, make it run more smoothly;

Color calibration unit, accurate positioning and printing of color bags, so that each bag presents a unified standard;

Trimming knife, using the upper and lower round knife way, so that trimming more accurate, smooth, durable and so on;

Servo motor is used to drag materials accurately;

Cutting knife unit, using high speed, wear-resistant, hard alloy steel blade;

Conveying table, movable mode is convenient for batch bag handling, making the work easier;

The machine frame adopts international standard steel plate, laser cutting molding, the Japanese assembly method, male and female buckle interpenetration screw locking, so that the strength of the fuselage to achieve the best state, two is not the traditional peer with channel steel plate welding, resulting in the fuselage strength is not enough, the service life is not long and easy to deformation;

Independent electrical control cabinet, equipped with man-machine interface.

四、细节展示:Show Detail

Paper bags are increasingly important in the 21st century because these bags are 100% reusable, recyclable and biodegradable, while being environmentally friendly an...

Reducing plastic is government and customer' top environmental concern.Using the paper products instead of the plastic products is a good choice.Firstly, the paper d...

During the period of widely using plastic products, the world saw the effects of non-biodegradable waste of plastic packaging on the global environment. There are so...

A paper bag is a bag made of paper, usually kraft paper. Paper bags are commonly used as shopping bags, packaging. Paper bags can be made from recycled paper, with s...

Paper carry bags are easily recyclable as compared to plastic carry bags and as an important role in environment. It is a very great opportunity to earn profit from ...