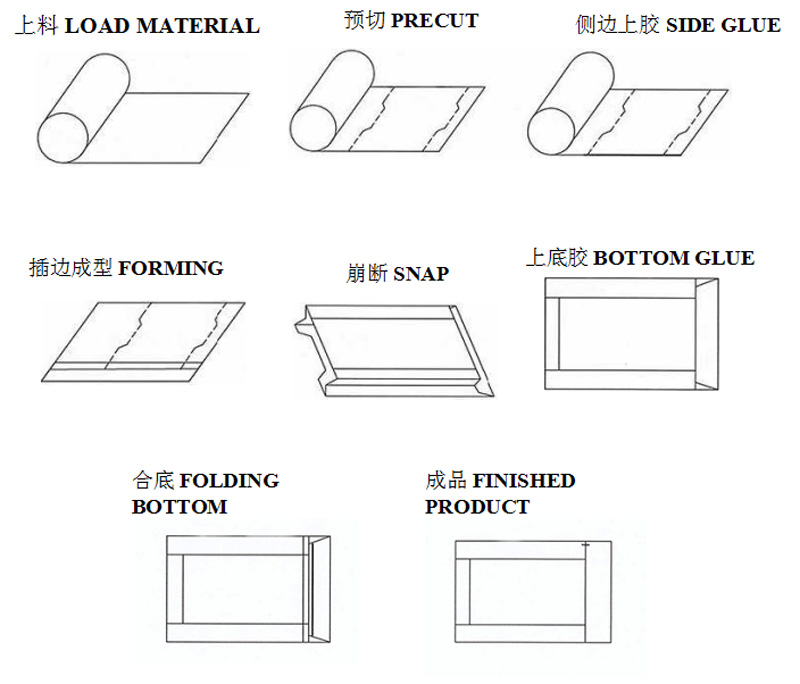

The high speed v bottom paper bag with film making machine use printed or original paper rolls like kraft paper, glossy paper, medical paper, etc as raw material. In the first, loading the paper roll (hydraulic feeding, automatic correction, constant tension)

Product Description

The high speed v bottom paper bag with film making machine use printed or original paper rolls like kraft paper, glossy paper, medical paper, etc as raw material. In the first, loading the paper roll (hydraulic feeding, automatic correction, constant tension), then through the film device to paste the paper and film together with the water based, then side gluing., precut, middle (side) seam gluing, color code tracking, raw material into a cylinder, fixed-length pulling and breaking, bottom gluing, bottom folding. It is an ideal equipment for producing bread paper bags.

Paper Bag Machine Parameter

|

Model |

HWJD270 |

HWJD350 |

|

Paper Grams |

35-80gsm |

35-80gsm |

|

Bag Tube Length |

155-360mm(4hub) |

155-400mm(4hub) |

|

(H) Step Height |

17mm |

17mm |

|

Bag Length |

95-355mm(4hub) |

150-395mm(4hub) |

|

Bag Width |

80-270mm |

80-350mm |

|

Speed |

50-500pcs/min |

50-500pcs/min |

|

Insert Paper Edge Depth |

10-60mm |

10-60mm |

|

Paper Roll Width |

220-810mm |

220-970mm |

|

Film width |

50-200mm |

50-200mm |

|

(OPP/PET)Film thickness |

0.012-0.037mm |

0.012-0.037mm |

Product Process

MACHINE DETAILS

|

|

Whole Servo System The original French SCHNEIDER servo motor is matched with the

|

|

|

Hydraulic loading Material loading and unloading adopts hydraulic |

|

Web Guiding The rectification of raw materials adopts |

|

|

Touch screen computer Using French SCHNEIDER touch screen man-machine interface,

|

|

|

|

Film Device Online to paste the film in the paper, |

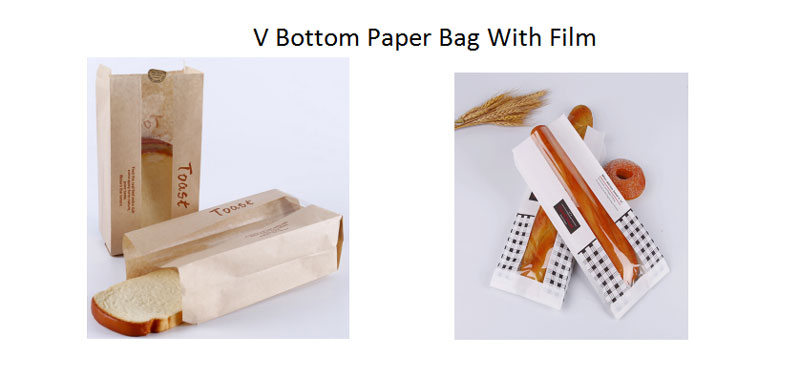

SAMPLE PICTURE:

PRODUCTS FEATURE:

1) 7 servos, 9 motors

7 servo control: precut, two traction rolls, press paper,snap,hub, conveyor belt

2 ordinary motors: glue pasting evenly, hydraulic loading material

2)Famous brand of configuration

3)Way out of the bag:collect the paper more easily and quickly

4)Heavy chassis: more stable operation

5)Intelligent out of glue:more save, more evenly

Our Service and Advantage

Packing:

Stretch film packing & in container.

FAQ:

Q: What is the whole business flow cooperation with us?

R: 1.Firstly,send your inquiry to us, make us have learned your requirement

We will be drawing a proforma invoice according to your requirement ,and start production after you finished to pay 30% deposit.

All of the goods, packing details, and B/L copy will be send to buyer after finished production. We will arrange shipment and provide original B/L after the buyer finished to pay the balance.

Q: What are the payment terms?

R: We can accept L/C,T/T,Western Union ,Money Gram.

Q:What is the quality of your machine?

R:Our products had passed ISO9001-2000 and CE identifications. And we focus on this area over 30 years. We have plenty of experience and advanced technology.

Our machines were exported to more than 96 countries so far. So also received a wide range of praise from customers. You do not need to doubt that we are one of the top in China.

Paper bags are increasingly important in the 21st century because these bags are 100% reusable, recyclable and biodegradable, while being environmentally friendly an...

Reducing plastic is government and customer' top environmental concern.Using the paper products instead of the plastic products is a good choice.Firstly, the paper d...

During the period of widely using plastic products, the world saw the effects of non-biodegradable waste of plastic packaging on the global environment. There are so...

A paper bag is a bag made of paper, usually kraft paper. Paper bags are commonly used as shopping bags, packaging. Paper bags can be made from recycled paper, with s...

Paper carry bags are easily recyclable as compared to plastic carry bags and as an important role in environment. It is a very great opportunity to earn profit from ...