The high speed v bottom paper bag machine is used for rolls of primary color paper or printing rolls such as kraft paper, glossy paper, medical paper, etc. The paper bag process consists of roll discharge (hydraulic feeding, automatic correction, constant tension)

Product Description

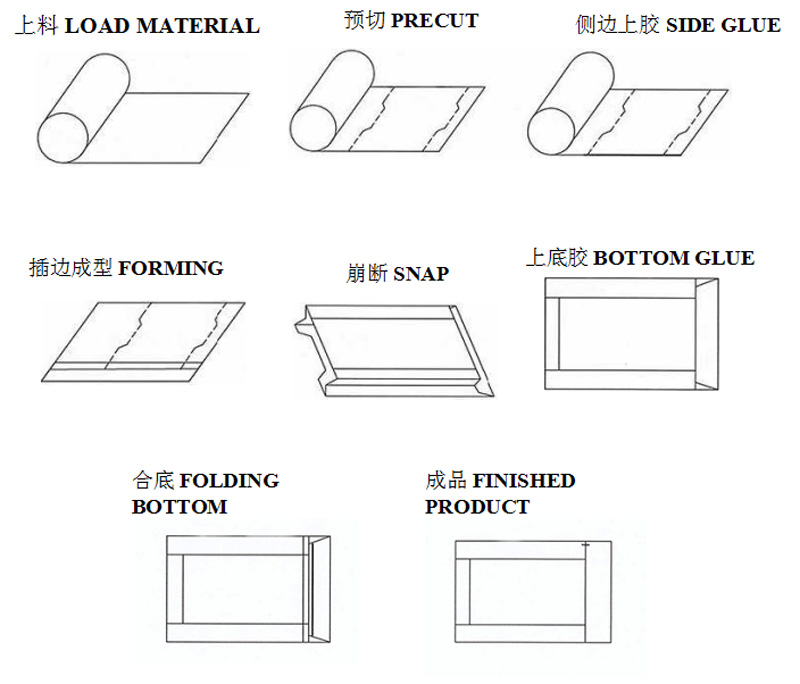

The high speed v bottom paper bag machine is used for rolls of primary color paper or printing rolls such as kraft paper, glossy paper, medical paper, etc. The paper bag process consists of roll discharge (hydraulic feeding, automatic correction, constant tension), precut, middle (side) seam gluing, color code tracking, raw material into a cylinder, fixed-length pulling and breaking, bottom gluing, bottom folding , The bottom of the bag is formed and finished in one time. This machine is easier to operate, more efficient, and more stable.

Paper bag machine parameter

|

Model |

HWJD-270 |

HWJD-350 |

|

|

Bag tube length |

155-360mm(4 hub) 365-450mm(2 hub) |

155-400mm(4 hub) 405-765mm(2 hub) |

|

|

L Paper bag length |

95-355mm(4 hub) 360-445mm(2 hub) |

150-395mm(4 hub) 400-760mm(2 hub) |

|

|

W Paper bag width |

80-270mm |

80-350mm |

|

|

M Inserted edge depth |

10-60mm |

10-60mm |

|

|

H Step height |

17mm |

17mm |

|

|

Paper bag speed |

50-500pcs/min |

50-500pcs/min |

|

|

Paper roll width |

220-810mm |

220-970mm |

|

|

Max roll paper diameter |

Φ1200mm |

Φ1200mm |

|

|

Inner diameter of paper |

Φ76mm(3”) |

Φ76mm(3”) |

|

|

Paper thickness |

35-80g/m² |

35-80g/m² |

|

|

Machine weight |

5000kg |

6000kg |

|

|

Machine size |

7100x2050x1850mm |

8500x2250x1850mm |

|

Product Process

MACHINE DETAILS

|

|

Whole Servo System The original French SCHNEIDER servo motor is matched

|

|

|

Hydraulic loading Material loading and unloading adopts hydraulic |

|

Web Guiding The rectification of raw materials adopts Italian SELECTRA, |

|

|

Touch screen computer Using French SCHNEIDER touch screen

|

|

SAMPLE PICTURE:

PRODUCTS FEATURE:

1) 7 servos, 9 motors

7 servo control: precut, two traction rolls, press paper,snap,hub, conveyor belt

2 ordinary motors: glue pasting evenly, hydraulic loading material

2) Way out of the bag:collect the paper more easily and quickly

3) Heavy chassis: more stable operation

4) Intelligent out of glue:more save, more evenly

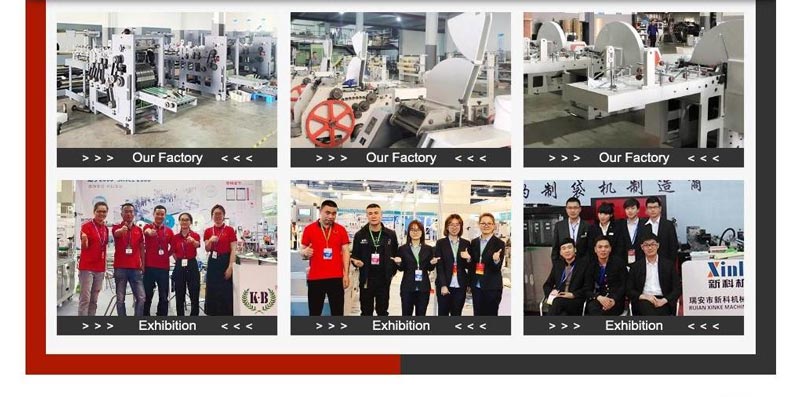

Our Service and Advantage

Packing:

Stretch film packing & in container.

FAQ:

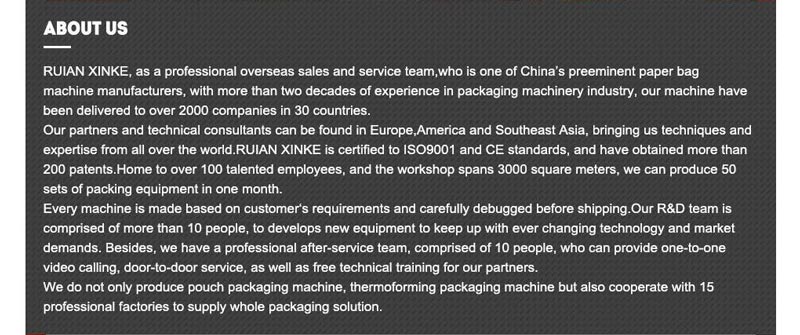

Q: Have your products been exported?

A: Yes, they have been exported to USA, Canada, Australia, Russia,Chile,Panama,Nicaragua, UAE, Saudi Arabia, Egypt, Sri Lanka, Nigeria, Iran, Vietnam, Indonisia, Singapore, Greece, Netherland, Georgia, Romania, Ireland, India, Thailand, Pakistan, Philippines, Singapore and so on.

Q: Can I request to change the form of packaging and transportation?

A: Yes, We can change the form of the packaging and transportation according to your request, but you have to bear their own costs incurred during this period and the spreads.

Q: Can you give me a discount?

A: Discount is available,but how much discounts is determined by the quantity,moreover,our price is very competitive in the field.

Q: How long history of your factory?

A: We have 20 years experience on machines, our products sell very well all over the world.

Q: Why I choose your company?

A: a) We are manufacturer

b) We have made machine about 25 years with strong experience and advanced technology.

c) Best Quality & Best Service with Competitive price.

d) 100% inspection Before Shipment, and got CE certificate.

e) We have Professional technical team, supply 24 hours service.

Paper bags are increasingly important in the 21st century because these bags are 100% reusable, recyclable and biodegradable, while being environmentally friendly an...

Reducing plastic is government and customer' top environmental concern.Using the paper products instead of the plastic products is a good choice.Firstly, the paper d...

During the period of widely using plastic products, the world saw the effects of non-biodegradable waste of plastic packaging on the global environment. There are so...

A paper bag is a bag made of paper, usually kraft paper. Paper bags are commonly used as shopping bags, packaging. Paper bags can be made from recycled paper, with s...

Paper carry bags are easily recyclable as compared to plastic carry bags and as an important role in environment. It is a very great opportunity to earn profit from ...