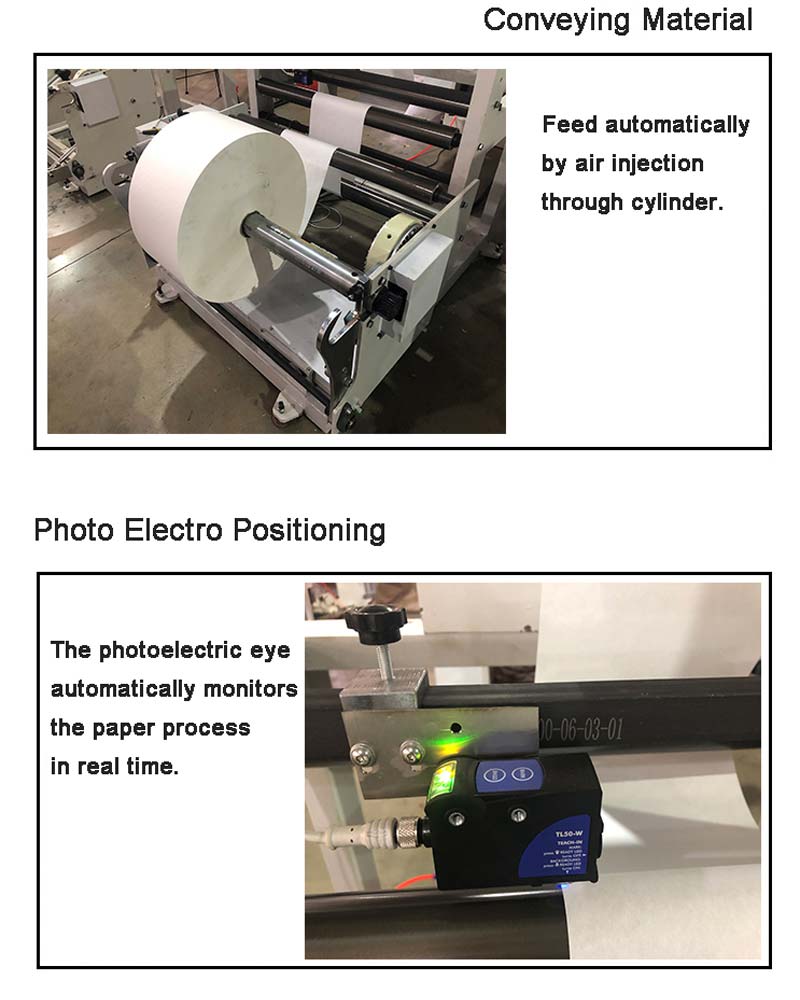

The common v bottom paper bag machine with inline printing machine is designed to manufacture v bottom paper bags. Using the paper rolling: kraft paper or white paper, through material loading, by the inline printing machine can print the logo or picture in the paper rolls.

Product Description

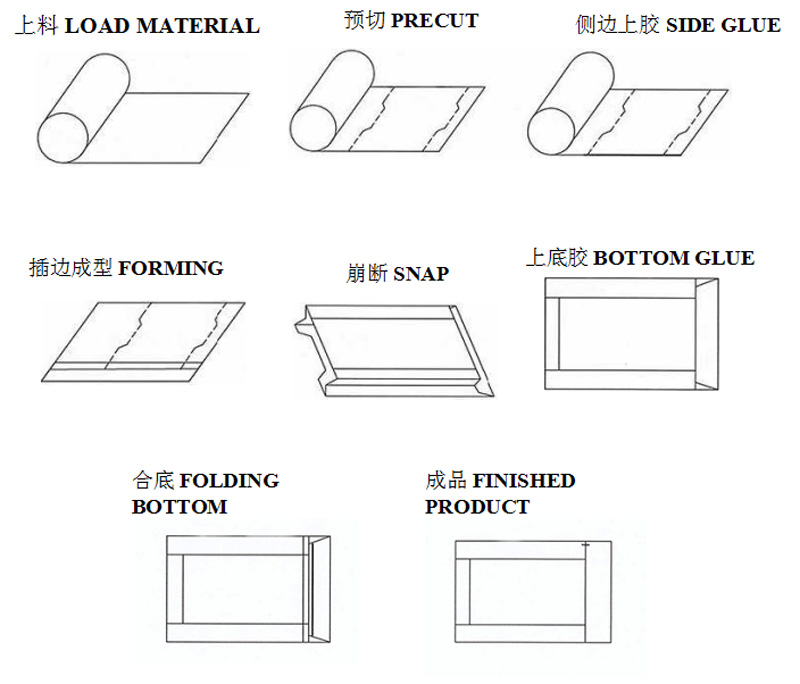

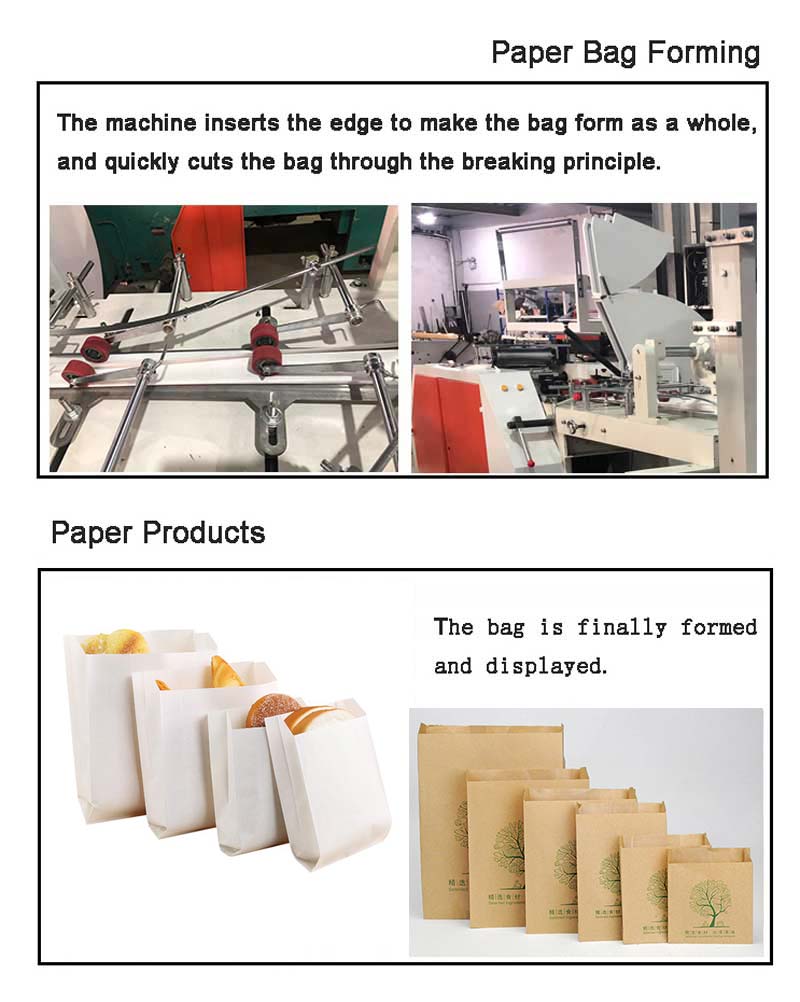

The common V bottom paper bag machine with inline printing machine is designed to manufacture v bottom paper bags. Using the paper rolling: kraft paper or white paper, through material loading, by the inline printing machine can print the logo or picture in the paper rolls, so with side gluing, forming, interrupt, bottom glue, folding bottom and output the v bottom bags with logos or pictures. It can produce different width bags, only change the plate, also can change the length by servo motor control.Strong structure ensures the quality and machine's life.

Paper Bag Machine Parameter

|

Model |

HWJD-400 |

HWJD-650 | HWJD-850 |

|

|

Width of Bag(mm) |

70-260 | 70-350 | 70-450 | |

|

Length of Bag(mm) |

120-450 |

150-750 | 150-750 | |

|

Paper Grams (g/m2) |

40-80g/m^2 |

40-80g/m^2 | 40-80g/m^2 | |

|

Paper Material Width (mm) |

200-740mm | 220-960mm | 220-1300mm | |

|

Max Speed (pcs/min) |

60-500pcs/min |

60-400pcs/min | 60-400pcs/min | |

|

Total Power(kw) |

7.5KW |

8KW | 10KW | |

|

Machine Weight(kg) |

1850KG |

3500KG | 5000KG | |

|

Machine Size |

4640x1470x1700mm |

5500x2100x1800mm | 6500x2500x2100mm |

Printing Machine Parameter

|

TYPE |

HWFP2800 |

HWFP4800 |

|

|

Max. Printing material width |

800mm |

800mm |

|

|

Max. Printing width |

760mm |

760mm |

|

|

Printing length range |

230-800mm |

230-800mm |

|

|

Printing speed |

5-100m∕min |

5-100m∕min |

|

|

Register precision |

≤±0.20mm |

≤±0.20mm |

|

|

Thickness of plate(including the thickness of double sides glue) |

2.28mm |

2.28mm |

Product Process

MACHINE DETAILS

SAMPLE PICTURE:

PRODUCTS FEATURE:

Our Service and Advantage

Packing:

Stretch film packing & in container.

FAQ:

Q:Where is your factory located?

A:In Ruian city, Zhejiang Province,China.

Q:Do you have a export licence?

A:Yes.

Q:Do you have after-sale service?

A:Yes, Good after-sale service, handling the customer complaint and solve problem for customers.

Q:How is the packing of products?

A:Stretch film packing.

Q.Is the sample available?

A:Yes, we are providing free samples are available for you to check the quality, customer need pay the delivery cost for the samples.

Paper bags are increasingly important in the 21st century because these bags are 100% reusable, recyclable and biodegradable, while being environmentally friendly an...

Reducing plastic is government and customer' top environmental concern.Using the paper products instead of the plastic products is a good choice.Firstly, the paper d...

During the period of widely using plastic products, the world saw the effects of non-biodegradable waste of plastic packaging on the global environment. There are so...

A paper bag is a bag made of paper, usually kraft paper. Paper bags are commonly used as shopping bags, packaging. Paper bags can be made from recycled paper, with s...

Paper carry bags are easily recyclable as compared to plastic carry bags and as an important role in environment. It is a very great opportunity to earn profit from ...