The paper shopping bag with twisted handle making machine used to produce the square bottom paper bags. This machine used with rope making machine, rewinding machine and twisted paper handle machine to produce the paper bag with twisted handle.

Product Description

The paper shopping bag with twisted handle making machine used to produce the square bottom paper bags. This machine used with rope making machine, rewinding machine and twisted paper handle machine to produce the paper bag with twisted handle. Such as shopping bags, shoes and clothing packaging bags, gift packaging bags, business bags and other varieties of hand-held paper bags. They are widely used in supermarket, bread shop. These machines can also be used in-line with flexographic printing press.

Paper Bag Machine Parameter

|

Model |

HWFD220 |

HWFD280 |

HWFD330 |

HWFD450 |

HWFD450B |

HWFD540 |

|

Bag Tube Length |

190-370mm |

270-530mm |

270-530mm |

285-530mm |

420-760mm |

420-760mm |

|

Bag Length |

150-320mm |

225-470mm |

225-470mm |

225-470mm |

320-680mm |

340-680mm |

|

Bag Width |

80-220mm |

120-280mm |

120-330mm |

220-450mm |

200-450mm |

250-540mm |

|

Bottom Width |

50-120mm |

60-160mm |

60-180mm |

80-220mm |

80-240mm |

120-260mm |

|

Side Edge Width |

20-30mm |

25-30mm |

25-30mm |

30mm |

30mm |

30-40mm |

|

Bottom Edge Width |

10-20mm |

15-25mm |

15-25mm |

20-30mm |

20-30mm |

20-30mm |

|

Paper Thickness |

50-130g/㎡ |

60-160g/㎡ |

60-160g/㎡ |

80-160g/㎡ |

80-160g/㎡ |

90-160g/㎡ |

|

Paper Inner Core Diameter |

ᴓ76mm(3”) |

ᴓ76mm(3”) |

76mm(3”) |

76mm(3”) |

76mm(3”) |

76mm(3”) |

|

Paper Roll Diameter |

ᴓ1300mm |

ᴓ1300mm |

ᴓ1300mm |

ᴓ1300mm |

ᴓ1300mm |

ᴓ1300mm |

|

Paper Roll Width |

280-710mm |

385-910mm |

385-1050mm |

630-1370mm |

590-1370mm |

770-1640mm |

|

Bag Making Speed |

30-200pcs/min |

30-180pcs/min |

30-160pcs/min |

30-150pcs/min |

30-120pcs/min |

30-120pcs/min |

|

Air Source |

≥0.12m³/m 0.6Mpa |

≥0.12m³/m 0.6Mpa |

≥0.12m³/m 0.6Mpa |

≥0.12m³/m 0.6Mpa |

≥0.12m³/m 0.6Mpa |

≥0.12m³/m 0.6Mpa |

|

Power Supply |

10kw |

12kw |

12kw |

12w |

16.5kw |

16.5kw |

|

Machine Weight |

5500kgs |

7000kgs |

8000kgs |

9000kgs |

10000kgs |

12000kgs |

|

Machine Dimension |

8000X2980X1800mm |

9700X2980X1900mm |

9800X3050X1900mm |

10200X3150X2200mm |

11265x3400x2200mm |

11250X3400X2160mm |

Twisted Handle Production Line

|

Max. External Diameter of Raw Paper Reel |

450mm |

|

|

Internal Diameter of Paper Reel |

76mm(3") |

|

|

Width of Paper Roll |

20-100mm |

|

|

Weight of Raw Paper |

15-60gsm |

|

|

Diameter of Paper Rope |

3mm-6mm |

|

|

Mould Size |

3mm,3.5mm,4mm,5mm,6mm |

|

|

Max. External Diameter of Paper Rope Reel |

300mm |

|

|

Production Speed |

30-40m/min*2 |

|

|

Power |

220V |

|

|

Total Power |

1.5kw |

|

|

Overall Dimension(L*W*H) |

1580*1440*930mm |

|

|

Total Weight |

300kg |

|

Inner Diameter of Raw Rope Roll |

76mm |

|

|

Inner Diameter of Final Rope Roll |

180mm |

|

|

Outer Diameter of Final Rope Roll |

400-600mm |

|

|

Max Production Speed |

150-180m/min |

|

|

Voltage |

380V |

|

|

Total Power |

2.2KW |

|

|

Total Weight |

150KG |

|

|

Dimension |

1050*800*1200mm |

|

Paper Roll Core Diameter |

76mm |

|

|

Paper Rope Diameter |

3-4mm |

|

|

Paper Rope height |

140mm |

|

|

Paper Width |

30-40mm |

|

|

Handle length |

152mm |

|

|

Power Requirements |

380v |

|

|

Total Power |

6KW |

|

|

Total Weight |

3400KG |

|

|

Overall Dimension |

6000*1600*1500mm |

|

|

Glue Type |

Hot-melt glue |

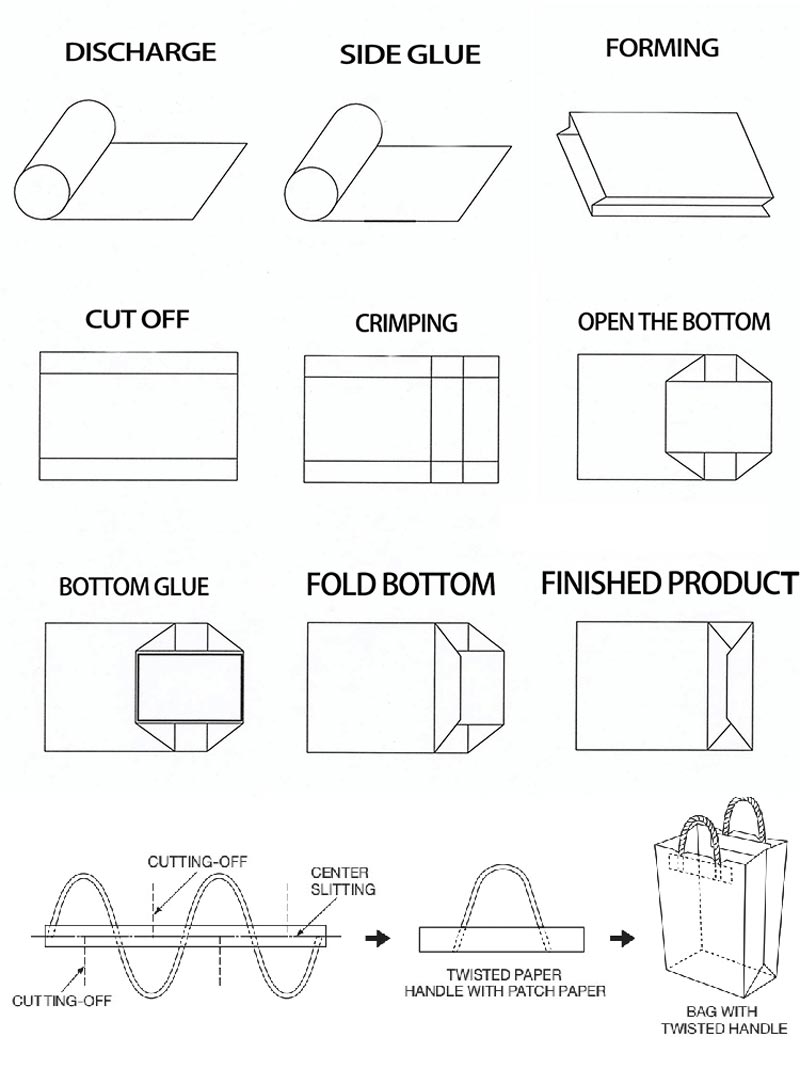

Product Process

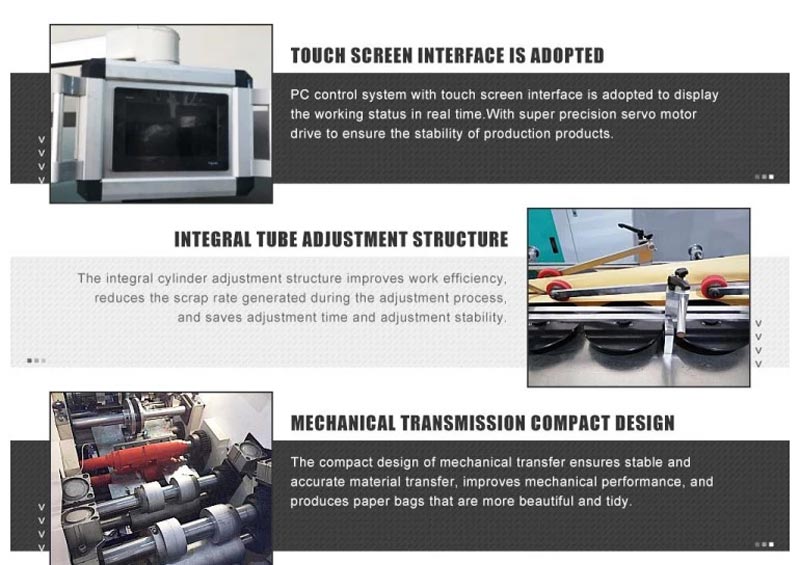

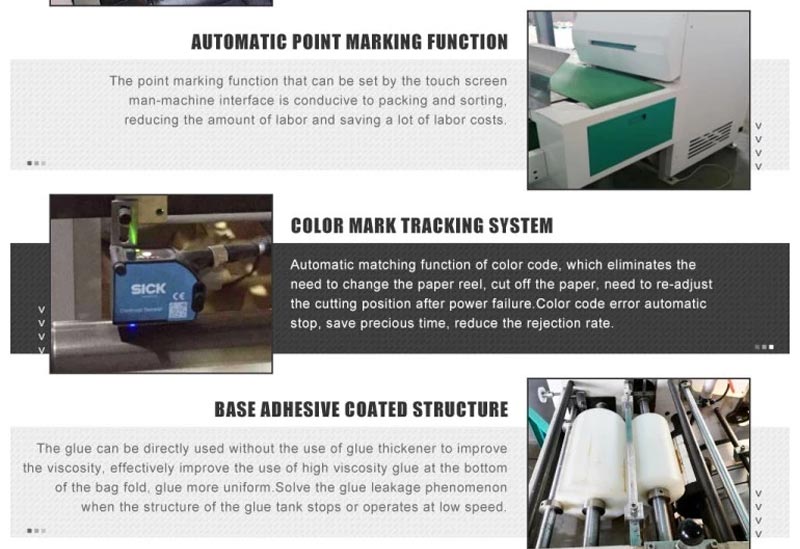

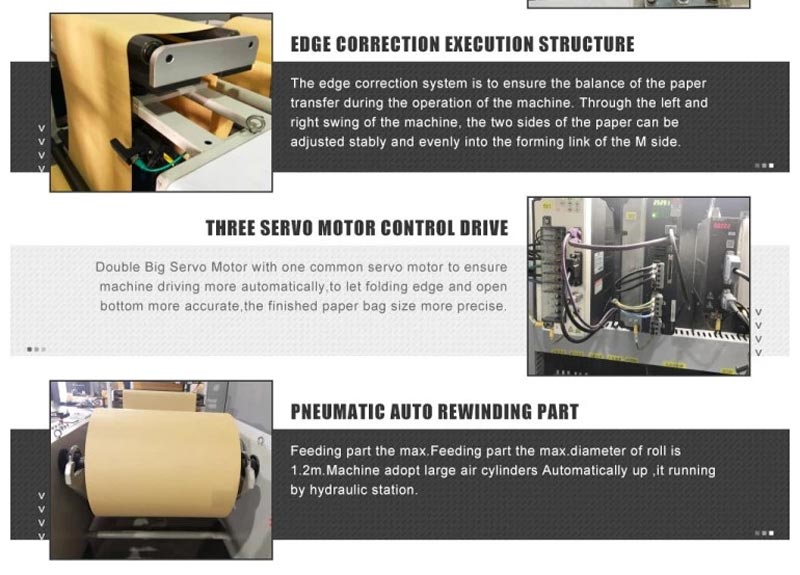

MACHINE DETAILS

SAMPLE PICTURE:

PRODUCTS FEATURE:

Our Service and Advantage

Packing:

Stretch film packing & in container.

FAQ:

Q: What can I buy from you?

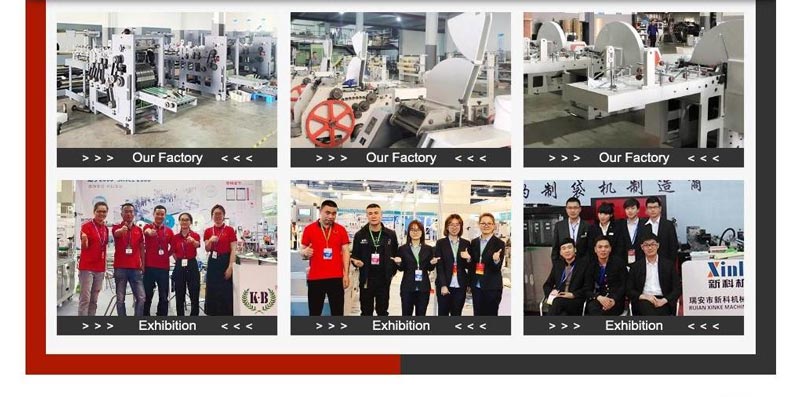

A: We produce the paper bag production line: sqaure bottom paper bag machine, v bottom paper bag machine, shopping bag machine, printing machine, slitting machine and handle machine. We also provide the raw materials: kraft paper, printed paper and glue.

Q: How long history of your factory?

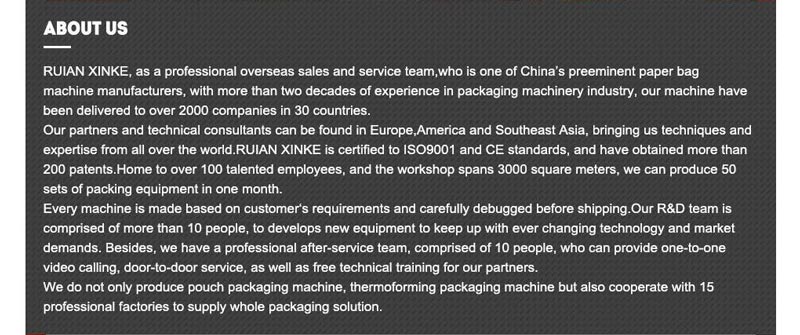

A: We have 20 years experience on machines, our products sell very well all over the world.

Q: How to solve the equipment trouble during using ?

A: Please email us about problem with pictures or a small video will be better,we will find the problem and solve it. If broken, we will send you a new free part if in the warranty period.

Q: Could you print our company LOGO on the nameplate and package?

A: Yes, we can do that.

Paper bags are increasingly important in the 21st century because these bags are 100% reusable, recyclable and biodegradable, while being environmentally friendly an...

Reducing plastic is government and customer' top environmental concern.Using the paper products instead of the plastic products is a good choice.Firstly, the paper d...

During the period of widely using plastic products, the world saw the effects of non-biodegradable waste of plastic packaging on the global environment. There are so...

A paper bag is a bag made of paper, usually kraft paper. Paper bags are commonly used as shopping bags, packaging. Paper bags can be made from recycled paper, with s...

Paper carry bags are easily recyclable as compared to plastic carry bags and as an important role in environment. It is a very great opportunity to earn profit from ...