Square bottom paper bag machine with inline printing can use the rolling paper online printing to produce square bottom paper bags at one time. According to customer needs, two / four-color printing machine inline can be customized.

Product Description

Square bottom paper bag machine with inline printing can use the rolling paper online printing to produce square bottom paper bags at one time. According to customer needs, two / four-color printing machine inline can be customized. This machine can produce various of paper bags, with fast speed, high production efficiency, is an ideal equipment for paper bag production. This machine is composed of rolling paper feed (hydraulic feeding, automatic deviation correction, constant tension), side glue, printing paper electric eye tracking, original paper into roll, fixed length traction cutting, bag bottom indentation opening bottom, bag bottom gluing folding forming and bag output. The whole machine is controlled by the computer central control system, the touch screen display, and the servo motor controls the length of the paper bag.

Paper Bag Machine Parameter

|

Model |

HWFD220 |

HWFD280 |

HWFD330 |

HWFD450 |

HWFD450B |

HWFD540 |

|

Bag Tube Length |

190-370mm |

270-530mm |

270-530mm |

285-530mm |

420-760mm |

420-760mm |

|

Bag Length |

150-320mm |

225-470mm |

225-470mm |

225-470mm |

320-680mm |

340-680mm |

|

Bag Width |

80-220mm |

120-280mm |

120-330mm |

220-450mm |

200-450mm |

250-540mm |

|

Bottom Width |

50-120mm |

60-160mm |

60-180mm |

80-220mm |

80-240mm |

120-260mm |

|

Side Edge Width |

20-30mm |

25-30mm |

25-30mm |

30mm |

30mm |

30-40mm |

|

Bottom Edge Width |

10-20mm |

15-25mm |

15-25mm |

20-30mm |

20-30mm |

20-30mm |

|

Paper Thickness |

50-130g/㎡ |

60-160g/㎡ |

60-160g/㎡ |

80-160g/㎡ |

80-160g/㎡ |

90-160g/㎡ |

|

Paper Inner Core Diameter |

ᴓ76mm(3”) |

ᴓ76mm(3”) |

76mm(3”) |

76mm(3”) |

76mm(3”) |

76mm(3”) |

|

Paper Roll Diameter |

ᴓ1300mm |

ᴓ1300mm |

ᴓ1300mm |

ᴓ1300mm |

ᴓ1300mm |

ᴓ1300mm |

|

Paper Roll Width |

280-710mm |

385-910mm |

385-1050mm |

630-1370mm |

590-1370mm |

770-1640mm |

|

Bag Making Speed |

30-200pcs/min |

30-180pcs/min |

30-160pcs/min |

30-150pcs/min |

30-120pcs/min |

30-120pcs/min |

|

Air Source |

≥0.12m³/m 0.6Mpa |

≥0.12m³/m 0.6Mpa |

≥0.12m³/m 0.6Mpa |

≥0.12m³/m 0.6Mpa |

≥0.12m³/m 0.6Mpa |

≥0.12m³/m 0.6Mpa |

|

Power Supply |

10kw |

12kw |

12kw |

12w |

16.5kw |

16.5kw |

|

Machine Weight |

5500kgs |

7000kgs |

8000kgs |

9000kgs |

10000kgs |

12000kgs |

|

Machine Dimension |

8000X2980X1800mm |

9700X2980X1900mm |

9800X3050X1900mm |

10200X3150X2200mm |

11265x3400x2200mm |

11250X3400X2160mm |

Printing Machine Parameter

|

TYPE |

HWFP2800 |

HWFP4800 |

HWFP21000 |

HWFP41000 |

|

Max. Printing material width |

800mm |

1000mm |

1000mm |

1000mm |

|

Max. Printing width |

760mm |

960mm |

960mm |

960mm |

|

Printing length range |

230-800mm |

230-800mm |

230-800mm |

230-800mm |

|

Printing speed |

5-100m∕min |

5-100m∕min |

5-100m∕min |

5-100m∕min |

|

Register precision |

≤±0.20mm |

≤±0.20mm |

≤±0.20mm |

≤±0.20mm |

|

Thickness of plate(including the thickness of double sides glue) |

2.28mm |

2.28mm |

2.28mm |

2.28mm |

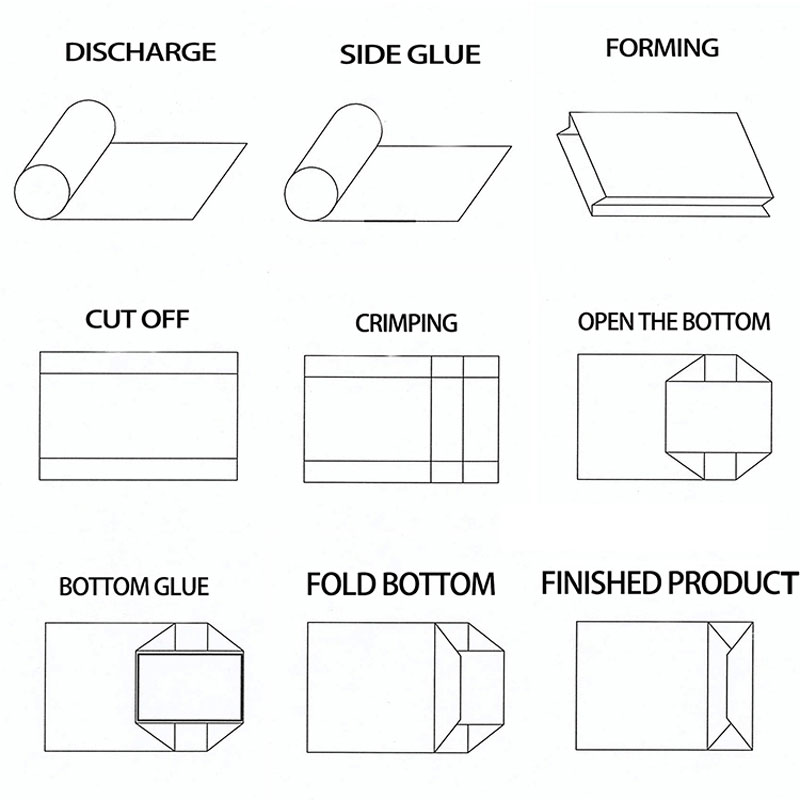

Product Process

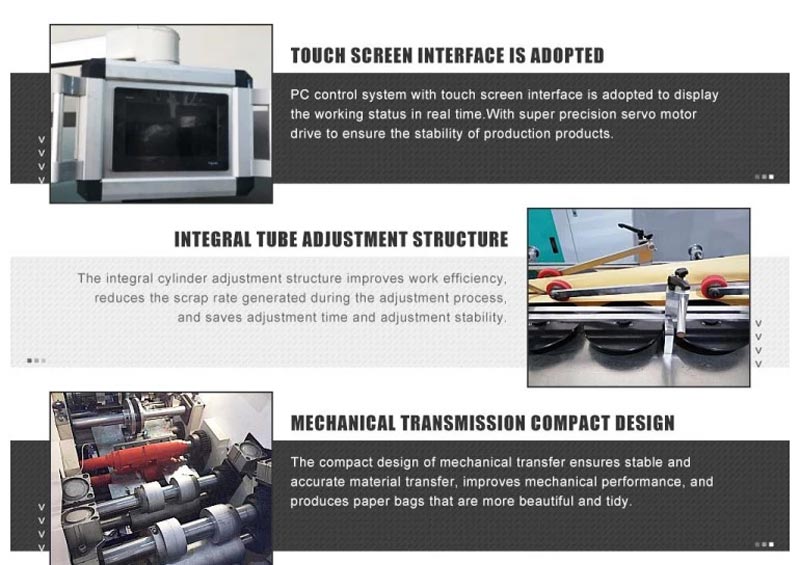

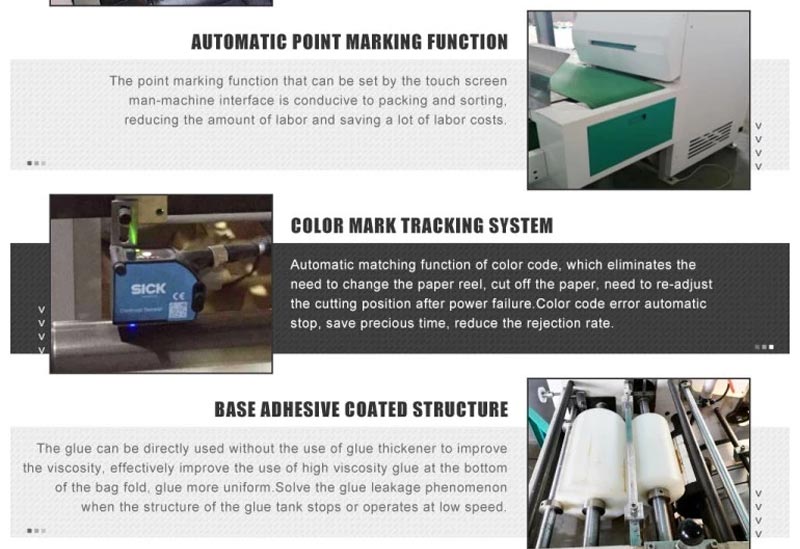

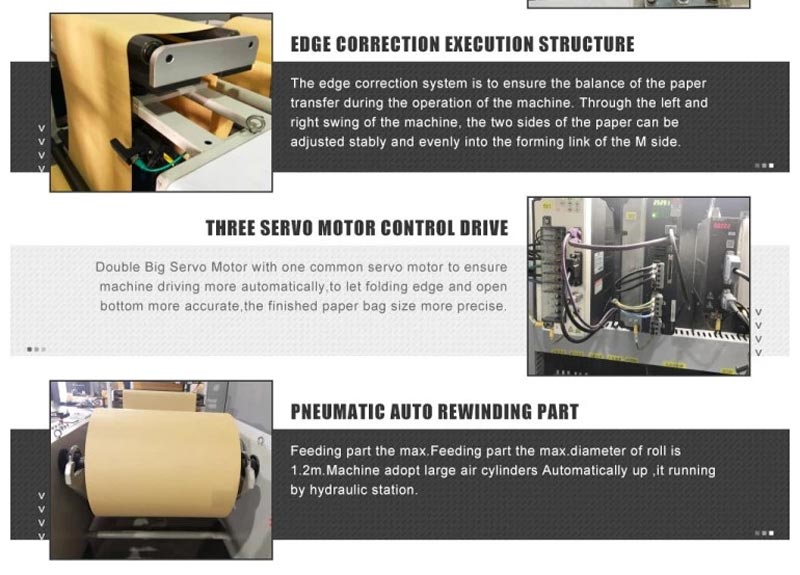

MACHINE DETAILS

SAMPLE PICTURE:

PRODUCTS FEATURE:

Our Service and Advantage

Packing:

Stretch film packing & in container.

FAQ:

Q: How does your factory do regarding quality control?

R: Quality is priority. Our Factory always attach great importance to quality controlling from the very beginning to the very end.

Q: How long is the warranty?

R: Within 1 year from date of the factory, if parts failure or damage (because of the quality problem ,except wearing parts)

Q: How to order?

R: 1.Please tell us what model and quantity you need.

2.We will make a PI for you to confirm the order details.

3.When we pay deposit, we will start to produce.

4.Finally we deliver the goods within the stipulated time.

Q: What is your after-sale service?

R: any questions will be sent within 24 hours via email, Skype, phone or Whatsapp/WeChat.

Q: Are you trading company or manufacturer?

R: We are manufacturer, and also provide the business solution to all the friends.

Paper bags are increasingly important in the 21st century because these bags are 100% reusable, recyclable and biodegradable, while being environmentally friendly an...

Reducing plastic is government and customer' top environmental concern.Using the paper products instead of the plastic products is a good choice.Firstly, the paper d...

During the period of widely using plastic products, the world saw the effects of non-biodegradable waste of plastic packaging on the global environment. There are so...

A paper bag is a bag made of paper, usually kraft paper. Paper bags are commonly used as shopping bags, packaging. Paper bags can be made from recycled paper, with s...

Paper carry bags are easily recyclable as compared to plastic carry bags and as an important role in environment. It is a very great opportunity to earn profit from ...