The square bottom paper patch bag making Machine use kraft paper roll and printed paper roll as raw material to produce the paper bags. The D cut handle is a extra function, it need to add D cut device in the standard square bottom paper bag machine to produce the paper bag with the D cut handle.

Product Description

The square bottom paper bag making Machine use kraft paper roll and printed paper roll as raw material to produce the paper bags. The D cut handle is a extra function, it need to add D cut device in the standard square bottom paper bag machine to produce the paper bag with the D cut handle. It can pretend 2 color /4 color printing group, bag surface window lamination device and handgrip hole device according to your need.

According to customer's requirements, it can be matched with rope twisting, flat rope handlebar machine, rewinding machine, etc., to make the products more competitive and diversified.

Paper Bag Machine Parameter

|

Model |

HWFD220 |

HWFD280 |

HWFD330 |

HWFD450 |

HWFD450B |

HWFD540 |

|

Bag Tube Length |

190-370mm |

270-530mm |

270-530mm |

285-530mm |

420-760mm |

420-760mm |

|

Bag Length |

150-320mm |

225-470mm |

225-470mm |

225-470mm |

320-680mm |

340-680mm |

|

Bag Width |

80-220mm |

120-280mm |

120-330mm |

220-450mm |

200-450mm |

250-540mm |

|

Bottom Width |

50-120mm |

60-160mm |

60-180mm |

80-220mm |

80-240mm |

120-260mm |

|

Side Edge Width |

20-30mm |

25-30mm |

25-30mm |

30mm |

30mm |

30-40mm |

|

Bottom Edge Width |

10-20mm |

15-25mm |

15-25mm |

20-30mm |

20-30mm |

20-30mm |

|

Paper Thickness |

50-130g/㎡ |

60-160g/㎡ |

60-160g/㎡ |

80-160g/㎡ |

80-160g/㎡ |

90-160g/㎡ |

|

Paper Inner Core Diameter |

ᴓ76mm(3”) |

ᴓ76mm(3”) |

76mm(3”) |

76mm(3”) |

76mm(3”) |

76mm(3”) |

|

Paper Roll Diameter |

ᴓ1300mm |

ᴓ1300mm |

ᴓ1300mm |

ᴓ1300mm |

ᴓ1300mm |

ᴓ1300mm |

|

Paper Roll Width |

280-710mm |

385-910mm |

385-1050mm |

630-1370mm |

590-1370mm |

770-1640mm |

|

Bag Making Speed |

30-200pcs/min |

30-180pcs/min |

30-160pcs/min |

30-150pcs/min |

30-120pcs/min |

30-120pcs/min |

|

Air Source |

≥0.12m³/m 0.6Mpa |

≥0.12m³/m 0.6Mpa |

≥0.12m³/m 0.6Mpa |

≥0.12m³/m 0.6Mpa |

≥0.12m³/m 0.6Mpa |

≥0.12m³/m 0.6Mpa |

|

Power Supply |

10kw |

12kw |

12kw |

12w |

16.5kw |

16.5kw |

|

Machine Weight |

5500kgs |

7000kgs |

8000kgs |

9000kgs |

10000kgs |

12000kgs |

|

Machine Dimension |

8000X2980X1800mm |

9700X2980X1900mm |

9800X3050X1900mm |

10200X3150X2200mm |

11265x3400x2200mm |

11250X3400X2160mm |

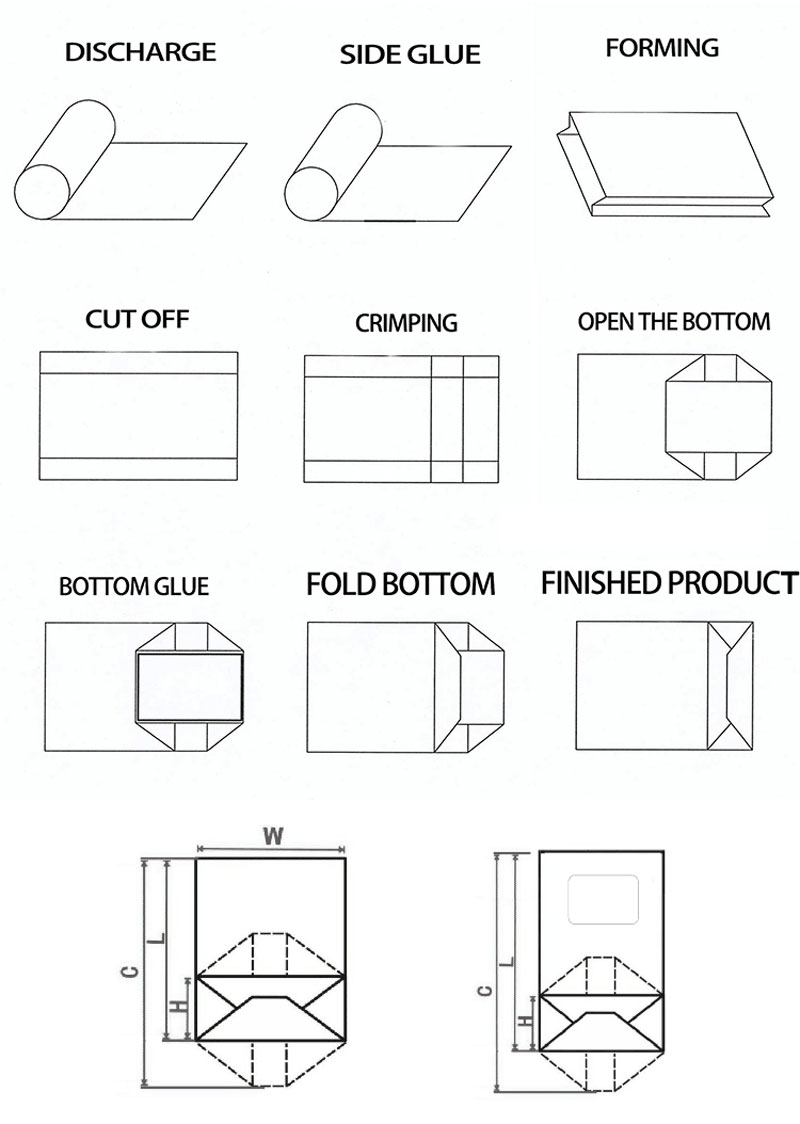

Product Process

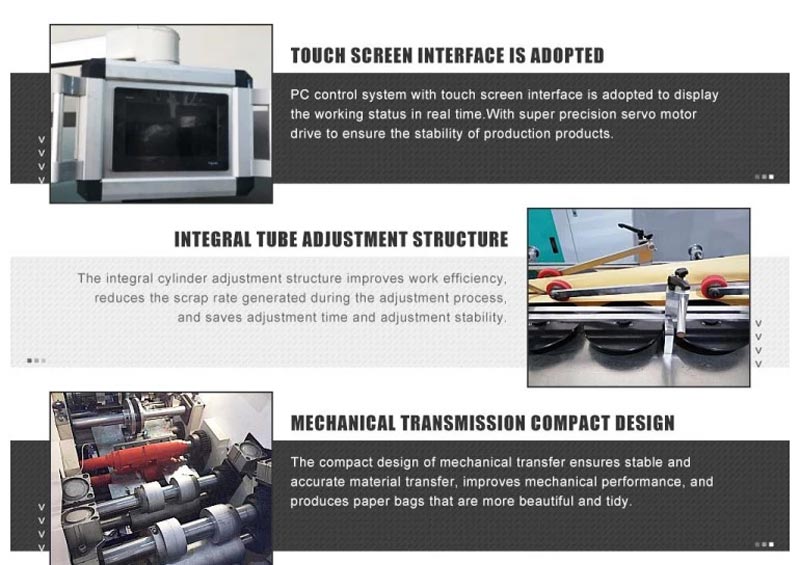

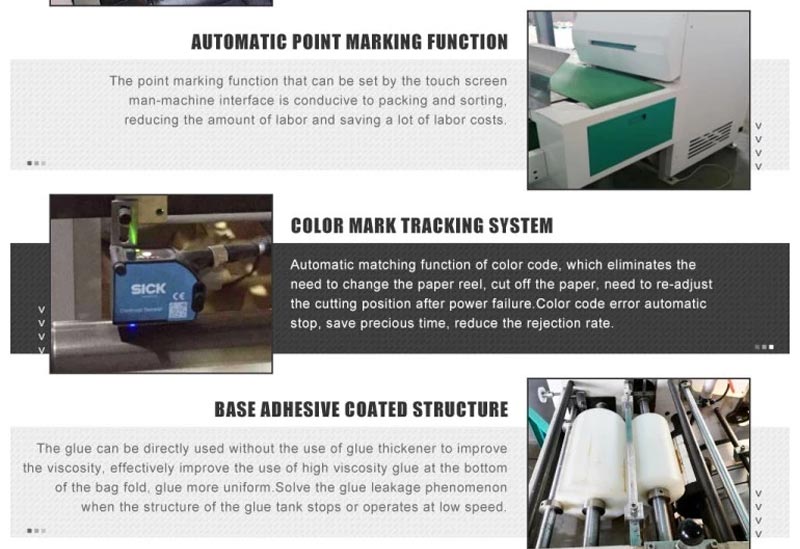

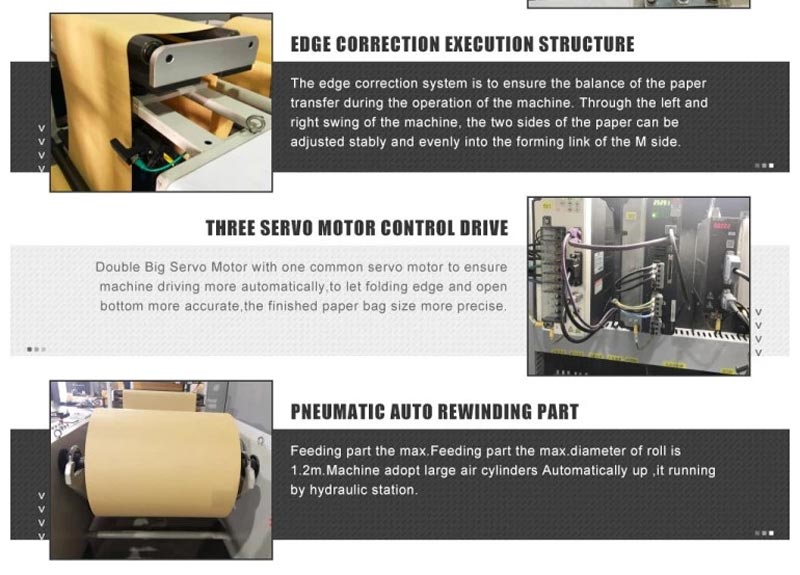

MACHINE DETAILS

SAMPLE PICTURE:

PRODUCTS FEATURE:

Our Service and Advantage

Packing:

Stretch film packing & in container.

FAQ:

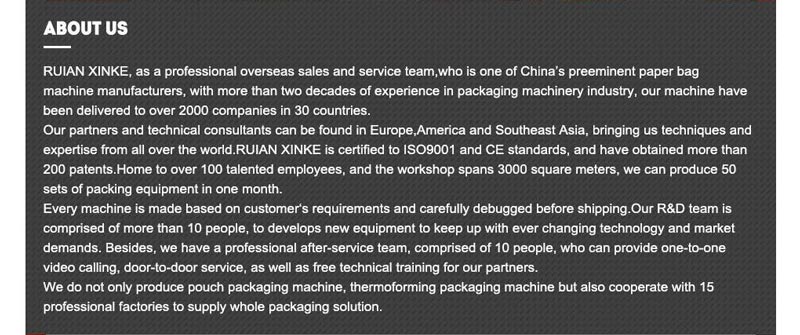

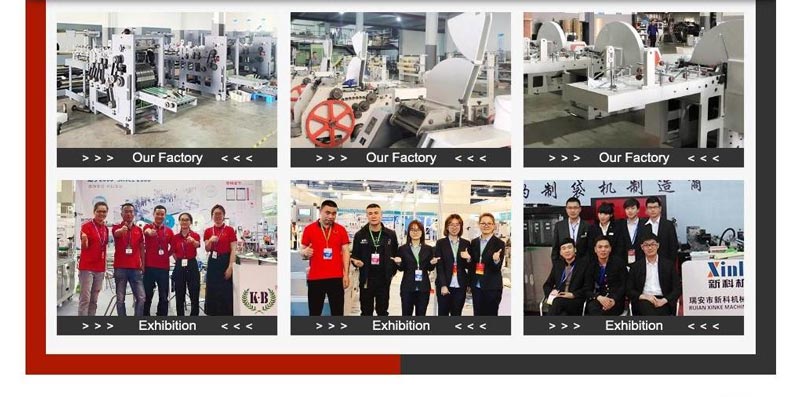

Q: Why choose our company?

A: We are China leading machine manufacturer.

Our company have 20 years with strong experience in manufacturing.

Best quality and service with reasonable price.

Q: Can we customize a suitable machine for ourselves.

A: Yes, we can produce the machine according to your requirement.

Q: Where is your factory located? How can I visit there?

A: Our factory is located in Ruian, Zhejing China.

Welcome to visit us. The nearest airport is Wenzhou airport. It's about 40 minutes by plane from Shanghai (5 hours by train).

Paper bags are increasingly important in the 21st century because these bags are 100% reusable, recyclable and biodegradable, while being environmentally friendly an...

Reducing plastic is government and customer' top environmental concern.Using the paper products instead of the plastic products is a good choice.Firstly, the paper d...

During the period of widely using plastic products, the world saw the effects of non-biodegradable waste of plastic packaging on the global environment. There are so...

A paper bag is a bag made of paper, usually kraft paper. Paper bags are commonly used as shopping bags, packaging. Paper bags can be made from recycled paper, with s...

Paper carry bags are easily recyclable as compared to plastic carry bags and as an important role in environment. It is a very great opportunity to earn profit from ...