Roll Feeding Square Bottom Paper Bag Making Machine forming the paper bag in one process from printed or unprinted roll paper , side gluing, roll folding, roll paper cutting, bottom folding, bottom gluing, bottom forming, bag formation at a stroke.

Product description:

|

Model |

HWFD220 |

HWFD280 |

HWFD330 |

HWFD450 |

HWFD450B |

HWFD540 |

|

Bag Tube Length |

190-370mm |

270-530mm |

270-530mm |

285-530mm |

420-760mm |

420-760mm |

|

Bag Length |

150-320mm |

225-470mm |

225-470mm |

225-470mm |

320-680mm |

340-680mm |

|

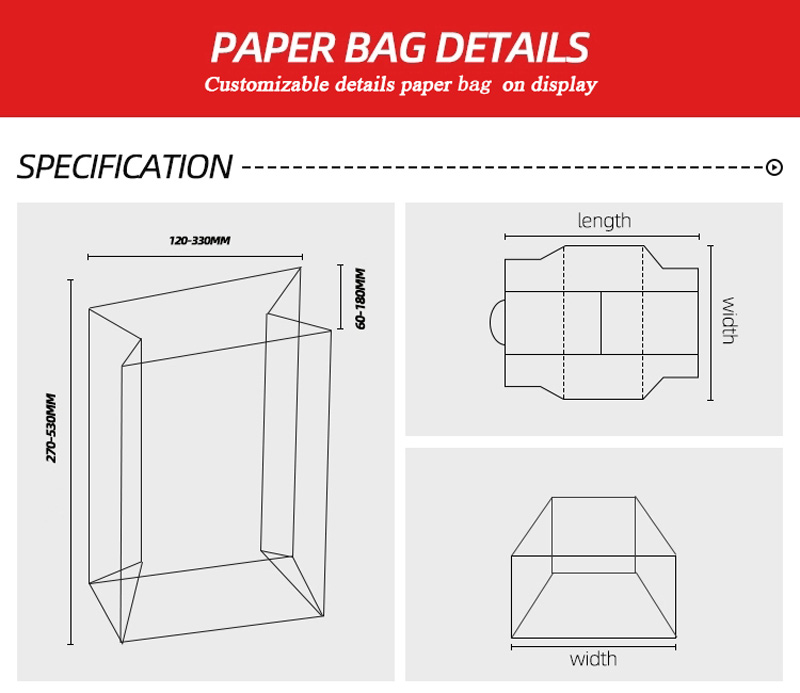

Bag Width |

80-220mm |

120-280mm |

120-330mm |

220-450mm |

200-450mm |

250-540mm |

|

Bottom Width |

50-120mm |

60-160mm |

60-180mm |

80-220mm |

80-240mm |

120-260mm |

|

Side Edge Width |

20-30mm |

25-30mm |

25-30mm |

30mm |

30mm |

30-40mm |

|

Bottom Edge Width |

10-20mm |

15-25mm |

15-25mm |

20-30mm |

20-30mm |

20-30mm |

|

Paper Thickness |

50-130g/㎡ |

60-160g/㎡ |

60-160g/㎡ |

80-160g/㎡ |

80-160g/㎡ |

90-160g/㎡ |

|

Paper Inner Core Diameter |

ᴓ76mm(3”) |

ᴓ76mm(3”) |

76mm(3”) |

76mm(3”) |

76mm(3”) |

76mm(3”) |

|

Paper Roll Diameter |

ᴓ1300mm |

ᴓ1300mm |

ᴓ1300mm |

ᴓ1300mm |

ᴓ1300mm |

ᴓ1300mm |

|

Paper Roll Width |

280-710mm |

385-910mm |

385-1050mm |

630-1370mm |

590-1370mm |

770-1640mm |

|

Bag Making Speed |

30-200pcs/min |

30-180pcs/min |

30-160pcs/min |

30-150pcs/min |

30-120pcs/min |

30-120pcs/min |

|

Air Source |

≥0.12m³/m 0.6Mpa |

≥0.12m³/m 0.6Mpa |

≥0.12m³/m 0.6Mpa |

≥0.12m³/m 0.6Mpa |

≥0.12m³/m 0.6Mpa |

≥0.12m³/m 0.6Mpa |

|

Power Supply |

10kw |

12kw |

12kw |

12w |

16.5kw |

16.5kw |

|

Machine Weight |

5500kgs |

7000kgs |

8000kgs |

9000kgs |

10000kgs |

12000kgs |

|

Machine Dimension |

8000X2980X1800mm |

9700X2980X1900mm |

9800X3050X1900mm |

10200X3150X2200mm |

11265x3400x2200mm |

11250X3400X2160mm |

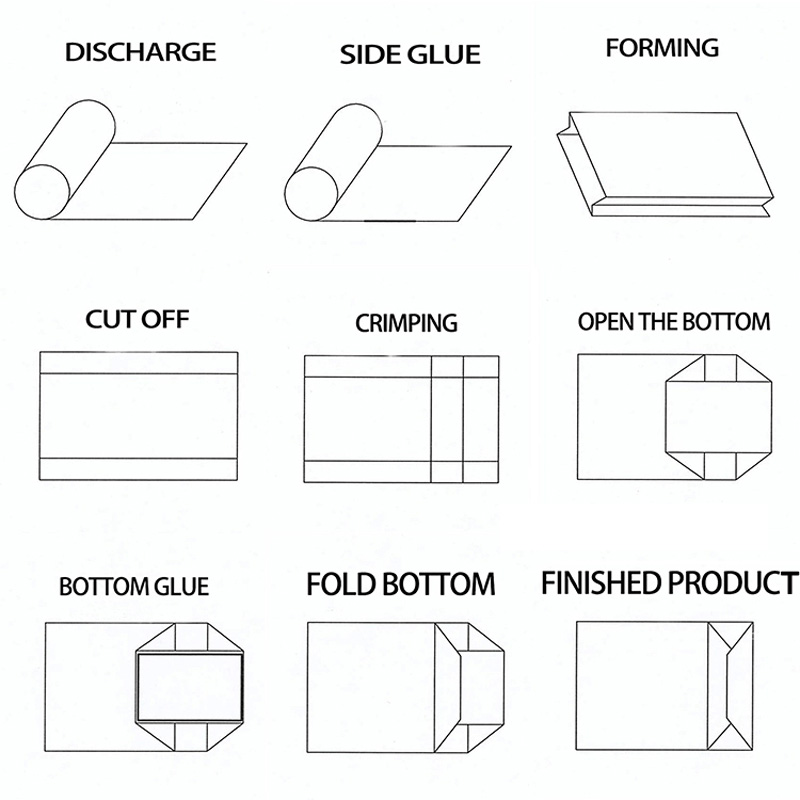

Forming Process:

Machine Details

Sample Picture:

PRODUCTS FEATURE:

OUR SERVICE:

OUR ADVANTAGE:

Packing:

Stretch film packing & in container.

FAQ:

Q: What about your main market?

A: We sell well both oversea market and domestic market. Our machines have gained great reputation at home and abroad.

Q: What about your service after sales?

A: You can contact us anytime when there is a problem, take a video if needed , we will reply within 12 hours and help solve the problem as we can.

Q: Does the machine power voltage meet buyer's factory power source ?

A: We can do it as your request.

Paper bags are increasingly important in the 21st century because these bags are 100% reusable, recyclable and biodegradable, while being environmentally friendly an...

Reducing plastic is government and customer' top environmental concern.Using the paper products instead of the plastic products is a good choice.Firstly, the paper d...

During the period of widely using plastic products, the world saw the effects of non-biodegradable waste of plastic packaging on the global environment. There are so...

A paper bag is a bag made of paper, usually kraft paper. Paper bags are commonly used as shopping bags, packaging. Paper bags can be made from recycled paper, with s...

Paper carry bags are easily recyclable as compared to plastic carry bags and as an important role in environment. It is a very great opportunity to earn profit from ...