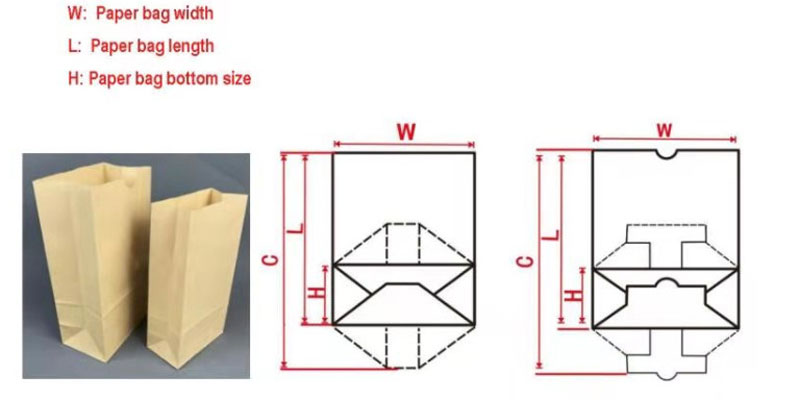

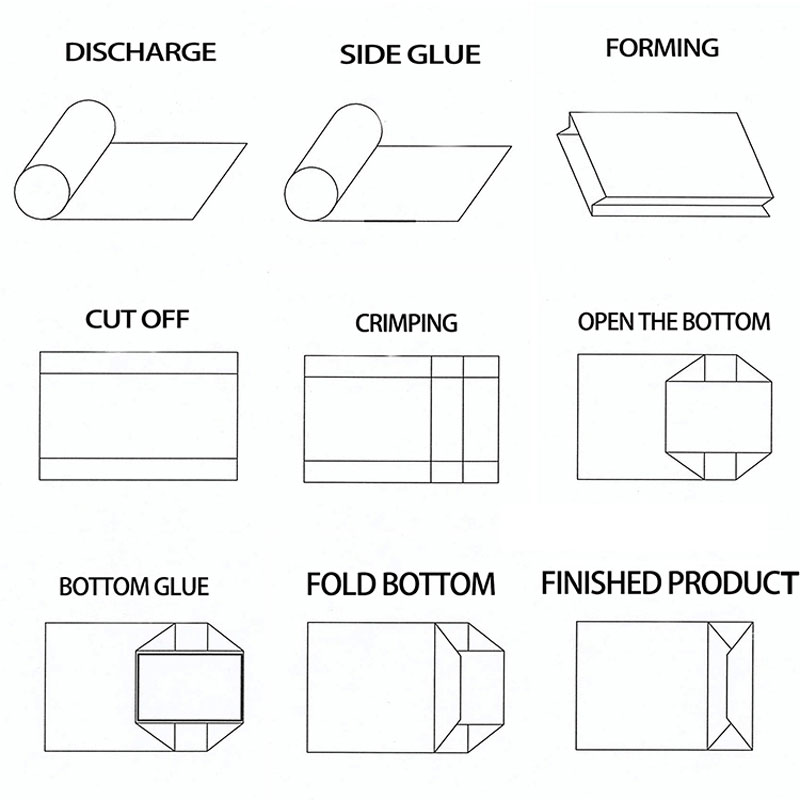

The square bottom paper bag making machine use the primary color paper roll or printed paper roll as raw materials through discharge, side glue, forming, cut off, crimping, bottom opened, bottom glue and fold bottom to produce the square bottom paper bags at one time.

Product Description

The square bottom paper bag making machine use the primary color paper roll or printed paper roll as raw materials through discharge, side glue, forming, cut off, crimping, bottom opened, bottom glue and fold bottom to produce the square bottom paper bags at one time. The whole machine is controlled by servo motor system, easy to adjust the length of paper bags. There are advantages:high speed, more wide range adjusting, easy to collect the bags etc.

Paper bag machine parameter

|

Model |

HWFD220 |

HWFD280 |

HWFD330 |

HWFD450 |

HWFD450B |

HWFD540 |

|

Bag Tube Length |

190-370mm |

270-530mm |

270-530mm |

285-530mm |

420-760mm |

420-760mm |

|

Bag Length |

150-320mm |

225-470mm |

225-470mm |

225-470mm |

320-680mm |

340-680mm |

|

Bag Width |

80-220mm |

120-280mm |

120-330mm |

220-450mm |

200-450mm |

250-540mm |

|

Bottom Width |

50-120mm |

60-160mm |

60-180mm |

80-220mm |

80-240mm |

120-260mm |

|

Side Edge Width |

20-30mm |

25-30mm |

25-30mm |

30mm |

30mm |

30-40mm |

|

Bottom Edge Width |

10-20mm |

15-25mm |

15-25mm |

20-30mm |

20-30mm |

20-30mm |

|

Paper Thickness |

50-130g/㎡ |

60-160g/㎡ |

60-160g/㎡ |

80-160g/㎡ |

80-160g/㎡ |

90-160g/㎡ |

|

Paper Inner Core Diameter |

ᴓ76mm(3”) |

ᴓ76mm(3”) |

76mm(3”) |

76mm(3”) |

76mm(3”) |

76mm(3”) |

|

Paper Roll Diameter |

ᴓ1300mm |

ᴓ1300mm |

ᴓ1300mm |

ᴓ1300mm |

ᴓ1300mm |

ᴓ1300mm |

|

Paper Roll Width |

280-710mm |

385-910mm |

385-1050mm |

630-1370mm |

590-1370mm |

770-1640mm |

|

Bag Making Speed |

30-200pcs/min |

30-180pcs/min |

30-160pcs/min |

30-150pcs/min |

30-120pcs/min |

30-120pcs/min |

|

Air Source |

≥0.12m³/m 0.6Mpa |

≥0.12m³/m 0.6Mpa |

≥0.12m³/m 0.6Mpa |

≥0.12m³/m 0.6Mpa |

≥0.12m³/m 0.6Mpa |

≥0.12m³/m 0.6Mpa |

|

Power Supply |

10kw |

12kw |

12kw |

12w |

16.5kw |

16.5kw |

|

Machine Weight |

5500kgs |

7000kgs |

8000kgs |

9000kgs |

10000kgs |

12000kgs |

|

Machine Dimension |

8000X2980X1800mm |

9700X2980X1900mm |

9800X3050X1900mm |

10200X3150X2200mm |

11265x3400x2200mm |

11250X3400X2160mm |

Product Process

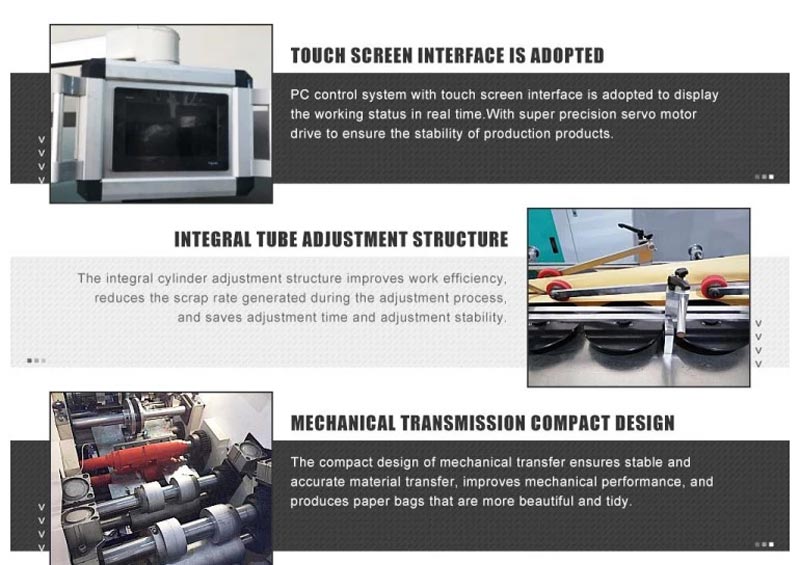

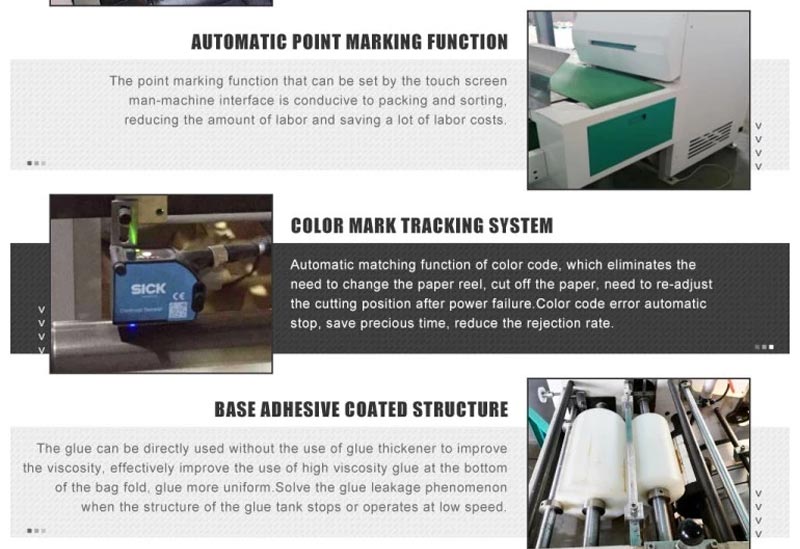

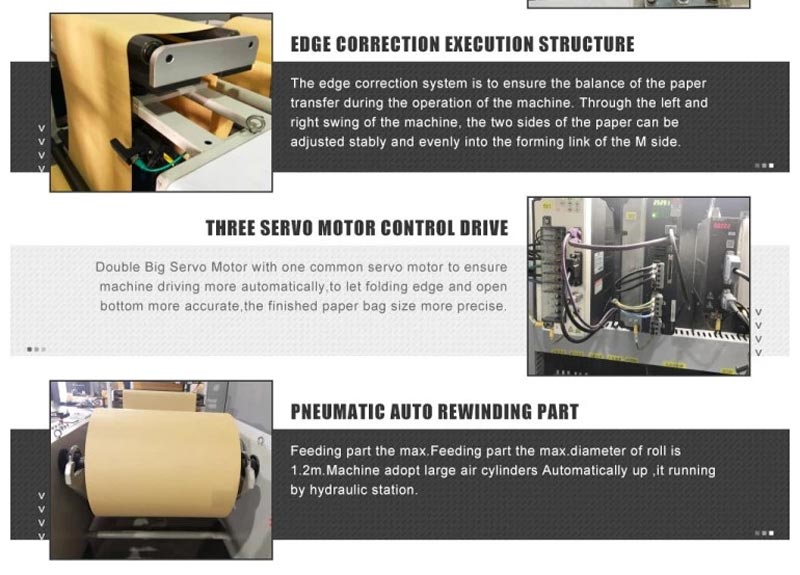

MACHINE DETAILS

SAMPLE PICTURE:

PRODUCTS FEATURE:

Our Service and Advantage

Packing:

Stretch film packing & in container.

FAQ:

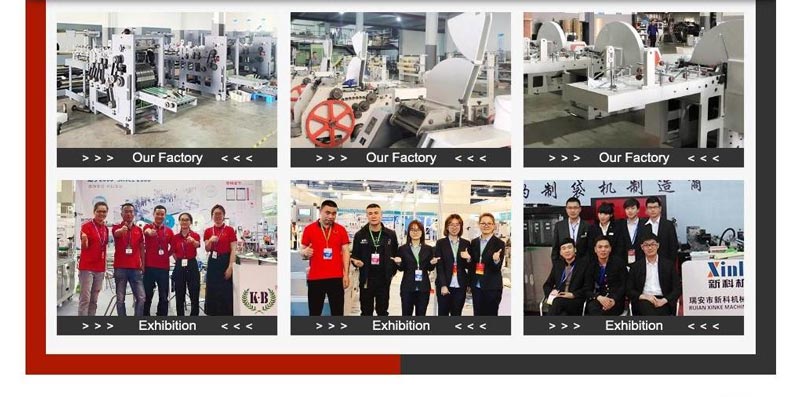

Q: Are you manufacturer or trading company?

A: We are the manufacturer.

Q: Where are your factories located? May I have a visit?

A: First of all,warmly welcome! Our factory located in Ruian city, Zhejiang Province

Q: Do you have machines in stock to sell?

A: No,we according to customers' requirements to manufacture the machine.

Q: How is the quality of your machine?

A: We have 20 years experience of manufacture the machine, choose the famous brand parts to produce the machine, the quality can be guaranteed.

Q: What about the lead time for mass production?

A: Honestly, it depends on the order quantity. Normally, the produce period is 35-60 days.

Q: What is your terms of delivery?

A: We accept EXW, FOB, CFR, CIF, etc. You can choose the one which is the most convenient or cost effective for you.

Paper bags are increasingly important in the 21st century because these bags are 100% reusable, recyclable and biodegradable, while being environmentally friendly an...

Reducing plastic is government and customer' top environmental concern.Using the paper products instead of the plastic products is a good choice.Firstly, the paper d...

During the period of widely using plastic products, the world saw the effects of non-biodegradable waste of plastic packaging on the global environment. There are so...

A paper bag is a bag made of paper, usually kraft paper. Paper bags are commonly used as shopping bags, packaging. Paper bags can be made from recycled paper, with s...

Paper carry bags are easily recyclable as compared to plastic carry bags and as an important role in environment. It is a very great opportunity to earn profit from ...