This machine is suitable for separating and cutting such various roll materials as BOPP, PET, CPP, CPE, PVC, aluminum foil and Paper Roll, etc. And can cut edge, separate and cut material according to different requirements during production.

Use:

This machine is suitable for separating and cutting such various roll materials as BOPP, PET, CPP, CPE, PVC, aluminum foil and Paper Roll, etc. And can cut edge, separate and cut material according to different requirements during production.

Feature

1)This machine install a round knife device, it can slit the rolls paper within 350g.

2)Independent master control screen, more flexible and even easier operation.

3)Automatic deviation-rectifying of releasing, photoelectric eye is suitable for tracking the edge and color of transparent material.

4)Releasing tension adopts magnetic powder clutch control.

5)Rolling adopts magnetic clutch control.

6)Automatic slitter edge blowing-inhaling device.

7)Automatic meter counting of material moving length.

Main Technical Specification

|

Model |

HWWS-1300A |

|

Slitting thickness |

20g-300g/m2 (Depending on different raw materials) |

|

Maximum diameter of raw material unwinding |

φ1200mm |

|

Maximum diameter of raw material winding |

Φ800mm |

|

Maximum width of cutting raw materials |

1300mm |

|

Rewinding key bar type air shaft |

φ74mm |

|

Number of reels to be taken up at the same time |

2 strips (single-axis rewinding possible) |

|

Correction accuracy |

±0.5mm |

|

Cutting accuracy |

±0.5mm |

|

speed |

10-200m/min |

|

total power |

14kw |

|

Body color |

Gray, white cover (other colors available) |

|

Using automatic photoelectric correction |

(Depends on different raw materials and customer specific requirements) |

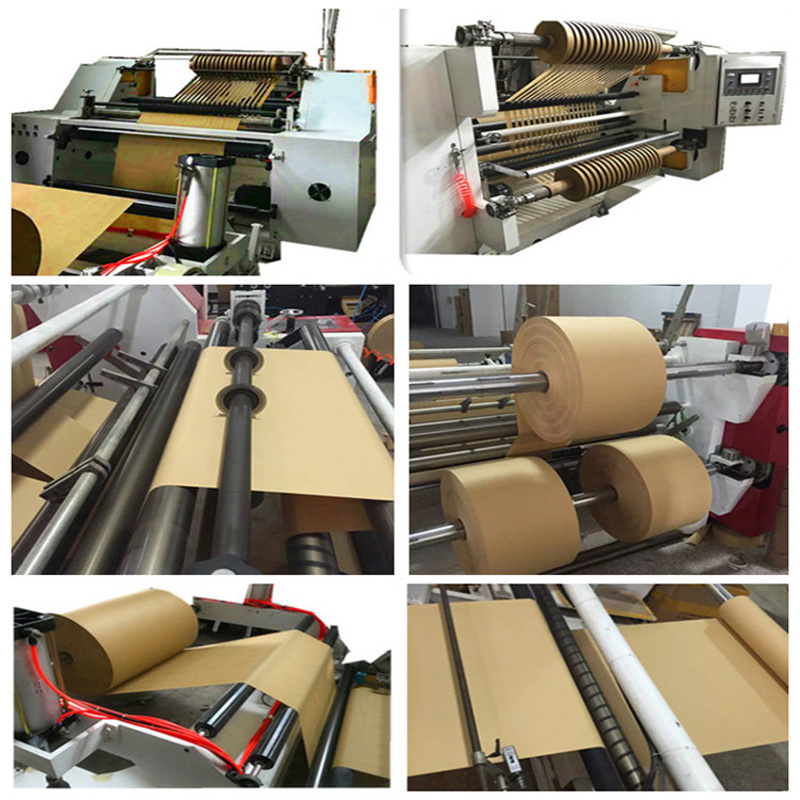

Details Photo:

Company Information:

FAQ:

Q1. Payment Terms

A1. TT 30% down payment, 70% before shipment.

Q2. Delivery Time

A2. 15-30 working days from the receipt of the down payment.

Q3. Machine installation

A3. XINKE could assign the technician to the place for the on-site installation if requested by the purchaser.

Q4. Technical Support

A4. Every machine is assigned by a specialist. The response is available within 12 hours while the solution for the troubleshooting is provided within 48 hours.

Q5. Demo and Testing

A5. Xinke built a training center for the clients and employees to study the machines operation. You are welcome to visit our factory anytime for the machines’ demo. Furthermore, we could run the machine with the materials provided by you and help you achieve your business efficiently.

Paper bags are increasingly important in the 21st century because these bags are 100% reusable, recyclable and biodegradable, while being environmentally friendly an...

Reducing plastic is government and customer' top environmental concern.Using the paper products instead of the plastic products is a good choice.Firstly, the paper d...

During the period of widely using plastic products, the world saw the effects of non-biodegradable waste of plastic packaging on the global environment. There are so...

A paper bag is a bag made of paper, usually kraft paper. Paper bags are commonly used as shopping bags, packaging. Paper bags can be made from recycled paper, with s...

Paper carry bags are easily recyclable as compared to plastic carry bags and as an important role in environment. It is a very great opportunity to earn profit from ...