This machine is suitable for separating and cutting such various roll materials as BOPP, PET, CPP, CPE, PVC, aluminum foil and Paper Roll, etc. And can cut edge, separate and cut material according to different requirements during production.

Use:

This machine is suitable for separating and cutting such various roll materials as BOPP, PET, CPP, CPE, PVC, aluminum foil and Paper Roll, etc. And can cut edge, separate and cut material according to different requirements during production.

Feature

1)This machine install a round knife device, it can slit the rolls paper within 350g.

2)Independent master control screen, more flexible and even easier operation.

3)Automatic deviation-rectifying of releasing, photoelectric eye is suitable for tracking the edge and color of transparent material.

4)Releasing tension adopts magnetic powder clutch control.

5)Rolling adopts magnetic clutch control.

6)Automatic slitter edge blowing-inhaling device.

7)Automatic meter counting of material moving length.

Main Technical Specification

|

Model |

HWFQ-1300A |

HWFQ-1600A |

|

Suitable material |

PE,PP, BOPP, PET,CPP,Paper, PVC, etc |

|

|

Max. Unwind diameter |

850mm |

850mm |

|

Max. Unwind width |

100-1300mm |

100-1600mm |

|

Paper core inner diameter |

76mm |

76mm |

|

Max. cutting width |

40-1300mm |

40-1600mm |

|

Machine max.speed |

10-200m/min |

10-200m/min |

|

Max. slitting speed |

10-170m/min (perforation running speed different) |

|

|

Rewind diameter |

40-600mm×2 roll(depend on roll width) |

|

|

Main motor |

4kw |

5.5KW |

|

Accurate of adjustment |

±0.5mm |

±0.5mm |

|

Total power |

6KW |

7.5KW |

|

Gross weight |

2500KG |

3300KG |

|

Overall size |

3200×2200×1700mm |

3200×2400×1700mm |

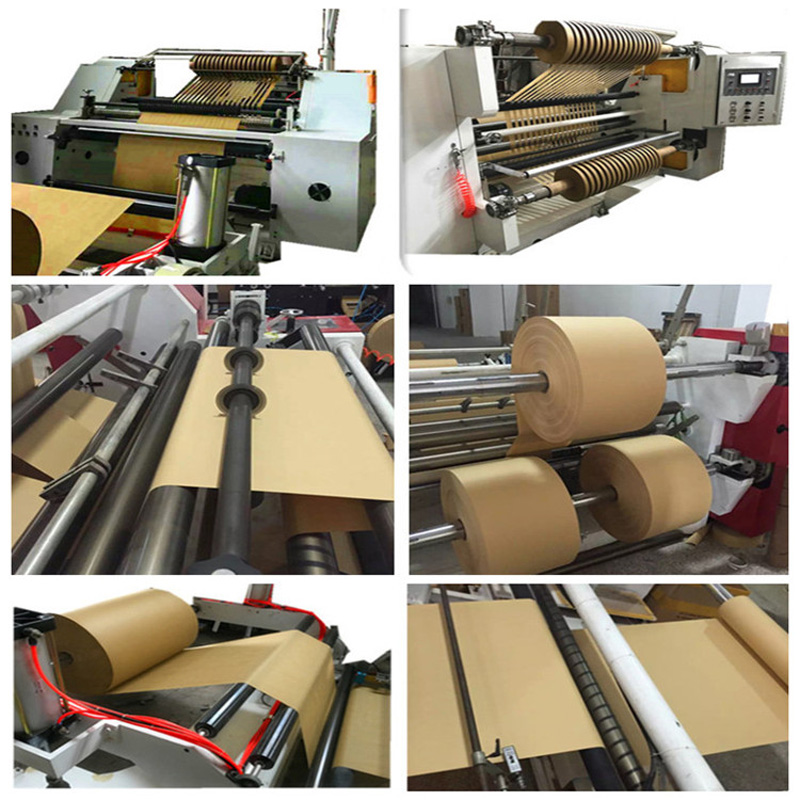

Details Photo:

Company Information:

FAQ:

1. When can I get the quotation?

We usually quote within 24 hours after we get your inquiry. If you are very urgent to get the price, please tell us so that we will regard your inquiry priority.

2.What about the lead time for whole line production?

15-30 working days for mass production.It depends on your quantity,and we will try our best to meet your needs.

3.What machines you have in your factory?

Paper bag making machine,paper bag printing machine and cutting machine and Disposable products making machine and so on.

Paper bags are increasingly important in the 21st century because these bags are 100% reusable, recyclable and biodegradable, while being environmentally friendly an...

Reducing plastic is government and customer' top environmental concern.Using the paper products instead of the plastic products is a good choice.Firstly, the paper d...

During the period of widely using plastic products, the world saw the effects of non-biodegradable waste of plastic packaging on the global environment. There are so...

A paper bag is a bag made of paper, usually kraft paper. Paper bags are commonly used as shopping bags, packaging. Paper bags can be made from recycled paper, with s...

Paper carry bags are easily recyclable as compared to plastic carry bags and as an important role in environment. It is a very great opportunity to earn profit from ...