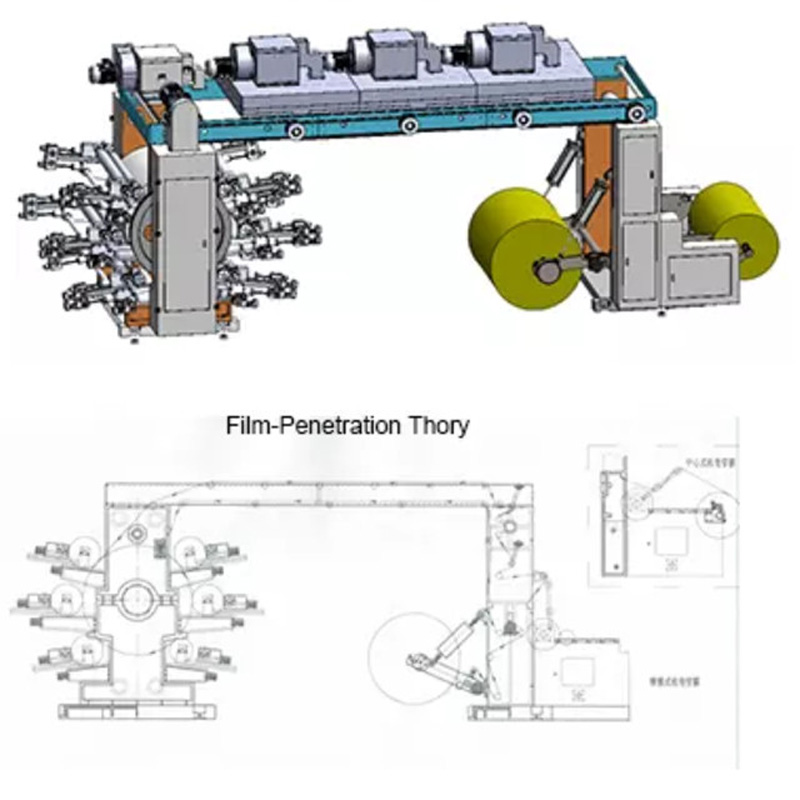

This machine is suitable for printing such packing materials as non-woven,polyethylene,PE,BOPP, polyethylene plastic bag glass paper and Roll Paper etc. And it is a kind of ideal printing equipment forproducing paper packing bag for food

Use:

This machine is suitable for printing such packing materials as non-woven,polyethylene,PE,BOPP, polyethylene plastic bag glass paper and Roll Paper etc. And it is a kind of ideal printing equipment forproducing paper packing bag for food, supermarket handbag, vest bag and clothes bag, etc.

Characteristics:

1.Reasonable structure, advanced technology, easy operation, stable performance, accurate color register.

2.Adopting high-quality motor, high-quality inverter, save the electricity, reduce the run fluctuation.

3.When the machine is stopped working, printing rolls still keep moving; when rise the printing roller ,ink motor running automatically ;when fallen the printing roller, ink motor stop running automatically.

4.The machine is equipped with blower and heater; and the heater employed central temperature control system.

5..The use of individual drying oven and cold wind system can effectively prevent the ink adhesion after printing.

6..Roller adopts special steel processing, and through special treatment, greatly reduce the beating range.

7.Printing roller uses static balance and dynamic balance processing, hard anode oxidation treatment, small resistance, beating small, achieves finally perfect printing effect.

8..Accurate printing effect achieved by special gear transmission device.

9.The printing machine all can choose advance configurations to achieve the high quality, the high-definition effect.

Suitable Material:

Kraft paper:40-350g/m² single-sided coated paper:30-350g/ m² copy paper:15-350g/ m² firecrackers and paper:40-350g/ m² paper money and incense:25-350g/ m² silicone paper:50-350g/ m² coated paper:30-350g/ m² dust-free paper:25-350g/ m² Release paper:40-350g/ m² composite paper:30-350g/ m²

PVC:10-120g/ m² OPP:10-120g/ m² PE :10-120g/ m² PET: 10-120g/ m² CPP:10-120g/ m²

woven:15-120g/ m² Weave fabric:15-500g/ m²

Printing Sample:

Main parameter:

|

Technical Specification |

|

|

Model |

HW-4800 |

|

Material feeding width |

800mm |

|

Max Printing Width |

760mm |

|

Material |

Paper.Non-woven fabric. Film. Aluminium foil. PVC.OPP.PE.BOPP.PE.NY.PET.CPP. |

|

Thickness of plate (including two-sided glue paper) |

1.7mm 2.28mm 3.94mm |

|

Printing length |

280-1000mm |

|

Printing speed |

10-70m/min |

|

Register precision |

±0.03mm |

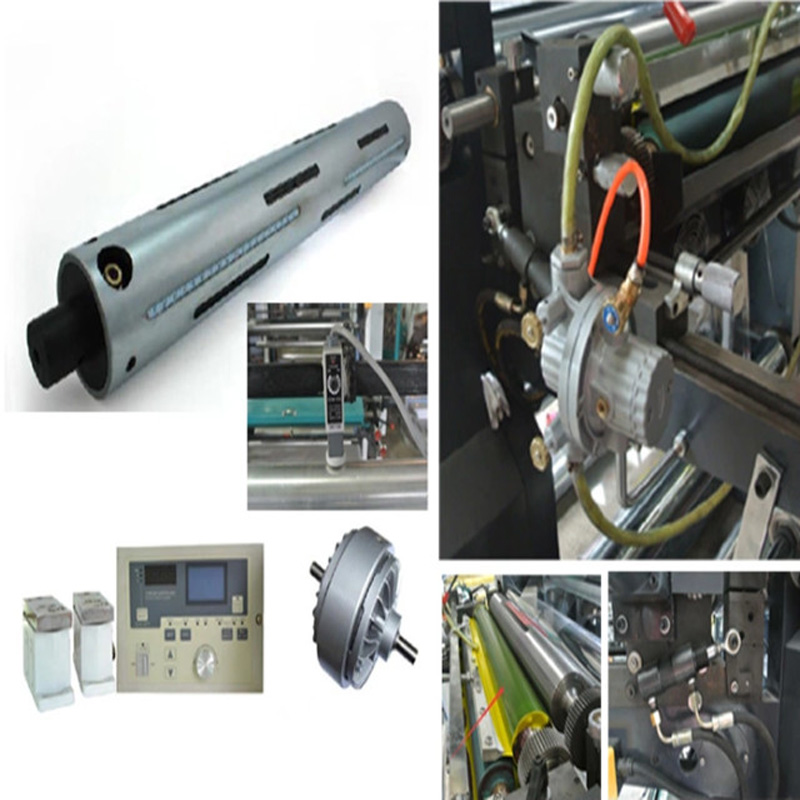

Details Photo:

Company Information:

FAQ:

A: How long is your delivery time?

A: The general delivery time is 30-45 days after receiving your order confirmation. Anther, if we have the goods in stock, it will only take 1-2 days.

B: Do you provide sample ? Is it free?

B: If the sample is low value, we will provide the free sample with freight collect. But for some high value samples, we need to collect the sample charge.

C: What is your term of payment?

C: 30% down payment before producing and 70% balance payment before shipping.

D: Which payment form you can accept?

D: T/T, L/C,Western Union, PayPal etc. We accept any convenient and swift payment term.

E: Which certificate do you have?

E: CE and ISO.

F: Do you have the test and audit service?

F: Yes, we can assist to get the designated test report for product and the designated factory audit report.

G: What’s is your shipping service?

G: We can provide services for vessel booking, goods consolidation, customs declaration, shipping documents preparation and delivery bulk at the shipping port.

F: Can you provide the FBA shipping service?

F: Yes, we have the good experience in providing the professional FBA service.

H: What’s your tem of the delivery?

H: Our ordinary delivery term is FOB Xiamen. We also accept EXW, CFR, CIF, DDP, DDU etc. We’ll offer you the shipping charges and you can choose the one which is the most convenient and effective for you.

Paper bags are increasingly important in the 21st century because these bags are 100% reusable, recyclable and biodegradable, while being environmentally friendly an...

Reducing plastic is government and customer' top environmental concern.Using the paper products instead of the plastic products is a good choice.Firstly, the paper d...

During the period of widely using plastic products, the world saw the effects of non-biodegradable waste of plastic packaging on the global environment. There are so...

A paper bag is a bag made of paper, usually kraft paper. Paper bags are commonly used as shopping bags, packaging. Paper bags can be made from recycled paper, with s...

Paper carry bags are easily recyclable as compared to plastic carry bags and as an important role in environment. It is a very great opportunity to earn profit from ...