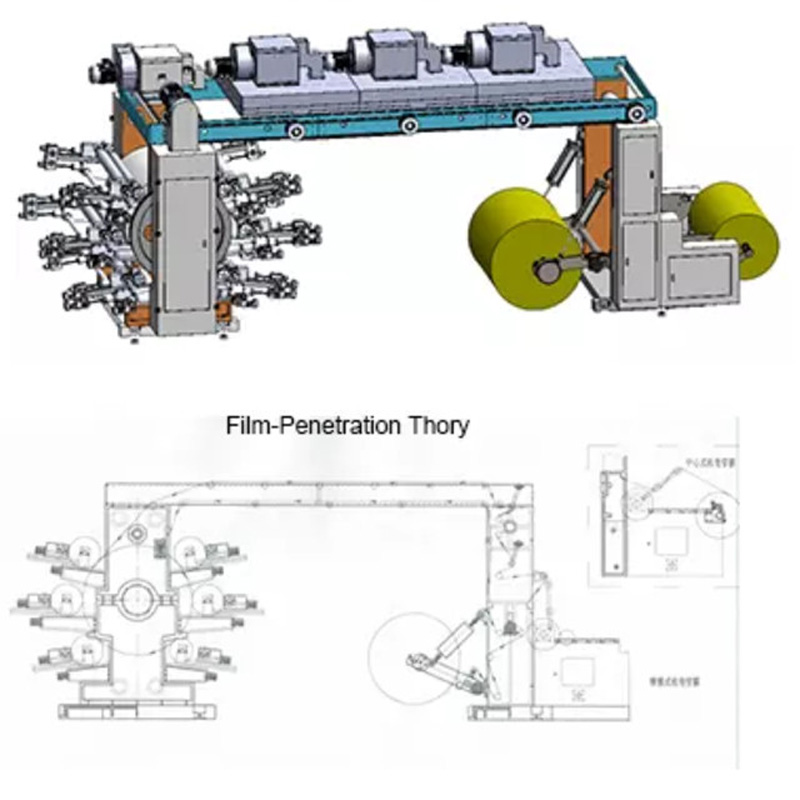

This machine is suitable for printing such packing materials as non-woven,polyethylene,PE,BOPP, polyethylene plastic bag glass paper and Roll Paper etc. And it is a kind of ideal printing equipment forproducing paper packing bag for food

Use:

This machine is suitable for printing such packing materials as non-woven,polyethylene,PE,BOPP, polyethylene plastic bag glass paper and Roll Paper etc. And it is a kind of ideal printing equipment forproducing paper packing bag for food, supermarket handbag, vest bag and clothes bag, etc.

Suitable Material:

Kraft paper:40-350g/m²

Single-sided coated paper:30-350g/ m²

Copy paper:15-350g/ m²

Firecrackers and paper:40-350g/ m²

Paper money and incense:25-350g/ m²

Silicone paper:50-350g/ m²

Coated paper:30-350g/ m²

Dust-free paper:25-350g/ m²

Release paper:40-350g/ m²

Composite paper:30-350g/ m²

PVC:10-120g/ m² OPP:10-120g/ m² PE :10-120g/ m² PET: 10-120g/ m² CPP:10-120g/ m²

woven:15-120g/ m² Weave fabric:15-500g/ m²

Feeding material part:

1.Single unwinder system, pneumatic/hydraulic loader or by manual for unwind system for you choose

2. Automatic stop machine when break the material; When machine stop, keep tension and avoid the material loose or line deflection.

3.Air shaft

4.EPC (edge position control): With manually/automatically/ central return function, can adjust the rewind move left and right .

5.Automatic tension control system with magnetic brake(5KG).

6.Roller core diameter: 76mm

7.Discharge maximum diameter: 1000mm

Printing sections:

1.Plate roller circumference: 300-1000mm, standard less than 400mm

2.Print material: resin plate or rubber plate

3.Transmission between printing roller and anilox roller: Helical gears

4.Printing chromatography: 360-degree rotation

5.Adjustment method: By Manual (Automatic printing after adjust by manual, when start machine, no need register color again, the printing pressure and register all keep the same.)

6.Printing roller lifting system: Automatic Hydraulic cylinder control roll up and down.

Drying system:

1.The machine is equipped with blower and heater; and the heater employed central temperature control system

2.Dry apparatus between each color, and one more dry apparatus after printing finished

Rewinding Part:

1.Single rewinder system, pneumatic/hydraulic loader or by manual for rewind system

2.Film central rewind system

3.Air shaft

4.Roller core diameter: 76mm

5.Discharge maximum diameter: 1000mm

Advantage:

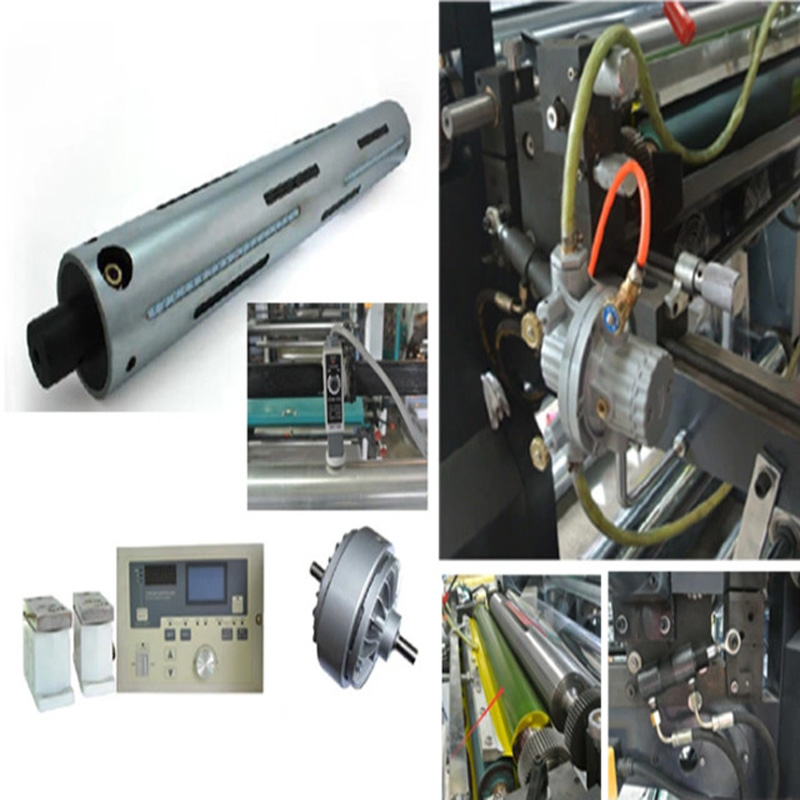

1.Reasonable structure, advanced technology, easy operation, stable performance, accurate color register.

2.Adopting high-quality motor, high-quality inverter, save the electricity, reduce the run fluctuation.

3.When the machine is stopped working, printing rolls still keep moving; when rise the printing roller ,ink motor running automatically ;when fallen the printing roller, ink motor stop running automatically.

4.The machine is equipped with blower and heater; and the heater employed central temperature control system.

5..The use of individual drying oven and cold wind system can effectively prevent the ink adhesion after printing.

6..Roller adopts special steel processing, and through special treatment, greatly reduce the beating range.

7.Printing roller uses static balance and dynamic balance processing, hard anode oxidation treatment, small resistance, beating small, achieves finally perfect printing effect.

8..Accurate printing effect achieved by special gear transmission device.

9.The printing machine all can choose advance configurations to achieve the high quality, the high-definition effect.

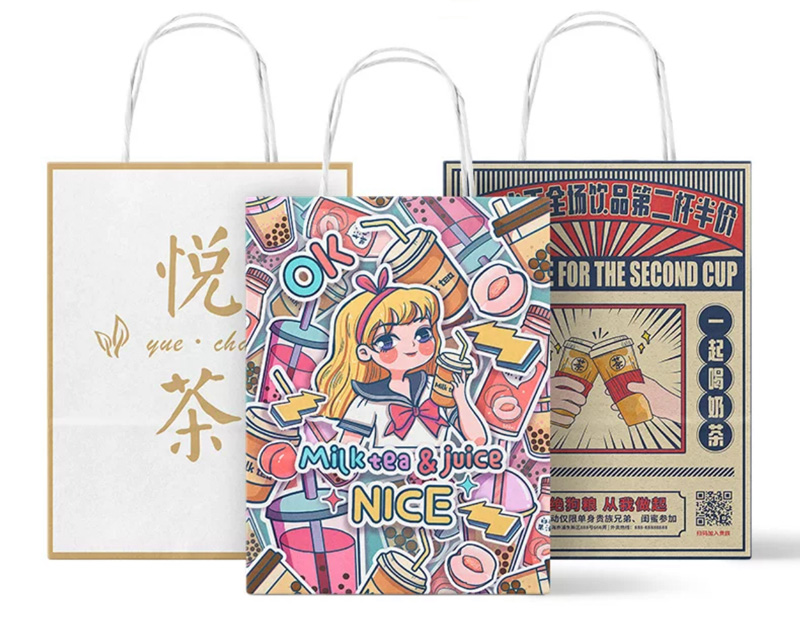

Printing Sample:

Main parameter:

|

Technical Specification |

|

|

Model |

HW-61000 |

|

Material feeding width |

1000mm |

|

9 |

|

|

Material |

Paper.Non-woven fabric. Film. Aluminium foil. PVC.OPP.PE.BOPP.PE.NY.PET.CPP. |

|

Thickness of plate (including two-sided glue paper) |

1.7mm 2.28mm 3.94mm |

|

Printing length |

280-1000mm |

|

Printing speed |

10-70m/min |

|

Register precision |

±0.03mm |

Details Photo:

Company Information:

FAQ:

1.Do you have a export licence?

We are a factory,but also a trade company ,we have expoprt licence.

2.Do you have after-sale service?

Yes, Good after-sale service, handling the customer complaint and solve problem for customers.

3.How is the packing of products?

Safe packing for long distance shipping. If machine is small we packing with wooden case.

4.Can you arrange shipment for customer?

Yes, very good experience in shipping, we work with the most reliable shipping companies in the world, such as OOCL, Mearsk, MSC,and etc.

Our Services:

1.Strong professional technical team ensure to produce the top quality products.

2.Special cost control system ensure to provide the most favorable price.

3.Rich experience on print bag line equipment.

4.Good knowledge on different market can meet special requirements.

5. Real manufacturer with our own factory located in Zhejiang China

Paper bags are increasingly important in the 21st century because these bags are 100% reusable, recyclable and biodegradable, while being environmentally friendly an...

Reducing plastic is government and customer' top environmental concern.Using the paper products instead of the plastic products is a good choice.Firstly, the paper d...

During the period of widely using plastic products, the world saw the effects of non-biodegradable waste of plastic packaging on the global environment. There are so...

A paper bag is a bag made of paper, usually kraft paper. Paper bags are commonly used as shopping bags, packaging. Paper bags can be made from recycled paper, with s...

Paper carry bags are easily recyclable as compared to plastic carry bags and as an important role in environment. It is a very great opportunity to earn profit from ...