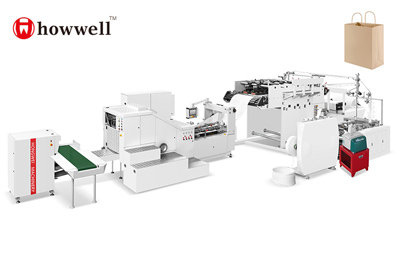

Automatic bag making machine manufacturers tell you the process of bag making machine

Know the automatic paper bag machine, but do you know the production process when the automatic paper bag machine is working? Today we are fortunate to invite Tiantian Youqing Machinery to tell us about it.

1. Preparations before starting the automatic paper bag machine

1. Check whether there is dust and debris around the automatic paper bag machine equipment, and remove them.

2. Enter the relevant data of bag making and the required number of each bundle.

3. Select the edge of the pattern with larger color difference to adjust the sensitivity of the photoeye to the left and right to meet the requirements.

4. Load the film rolls according to the requirements of the production notice.

5. Adjust the size of the bag according to the production notice and process documents, install the heat-sealing knife, and initially adjust the positions of the slitting knife and the heat-sealing knife.

6. Turn on the power of the automatic paper bag machine, and set the temperature of the heat-sealing knife according to the requirements of the process documents.

Turn on the automatic paper bag machine

1. Start the main motor of the automatic paper bag machine, run at low speed, and then adjust the edge position control to halve the film in the middle position.

2. Adjust the left and right nip rollers to align the left and right films, and adjust the front and back nip rollers to align the patterns.

3. During the production process, observe the bag situation of the fully automatic paper bag mechanism at any time and find abnormalities, and adjust immediately.

4. The machine quality inspector will carry out the inspection. After the inspection is qualified, the certificate will be attached and sent to the quality inspection room for random inspection.

5. Arrange the bags produced, and select the bags with quality defects and tie them up according to regulations.

6. Preliminarily adjust the machine speed, take a flat sample bag for preliminary inspection, if it does not meet the specified requirements, take a step flat sample bag for heat-sealing value test.

7. Adjust the slitting blade of the automatic paper bag machine to the desired position, and adjust the punching position to the scissors mouth.

8. Adjust the heat-sealing knife of the automatic paper bag machine to make the heat-sealing within the required range of the bag.

Shutdown of the automatic bag making machine

1. Turn off the main power switch of the automatic paper bag machine, and then turn off the power switches of each part.

2. Make a record of on-duty and require accuracy and cleanliness.

3. Clean the sanitation of the automatic paper bag machine and site san

itation, and send the products to the general inspection room.

packing

1. Inspection: The machine quality inspector will inspect the quantity and quality one by one. After the quantity and quality are all qualified, they are packed into the box as required and put into the packing list; the unqualified products selected are placed in the Inside the carton marked “Qualified”.

2. Packing: The machine personnel sort out the products in this process, select the unqualified products with quality defects, bundle the qualified products, and hand them to the machine quality inspector for inspection.

3. The general quality inspector will conduct random inspections on the products submitted for inspection according to the specified proportion, and pack them into warehouse after passing the inspection.

4. The machine personnel send the products on duty to the appearance quality inspection room.

Español

Español Français

Français